Ipayipi lokujikeleza kwethangi lamanzi isifudumezi sikagesi

Isimiso sokusebenza

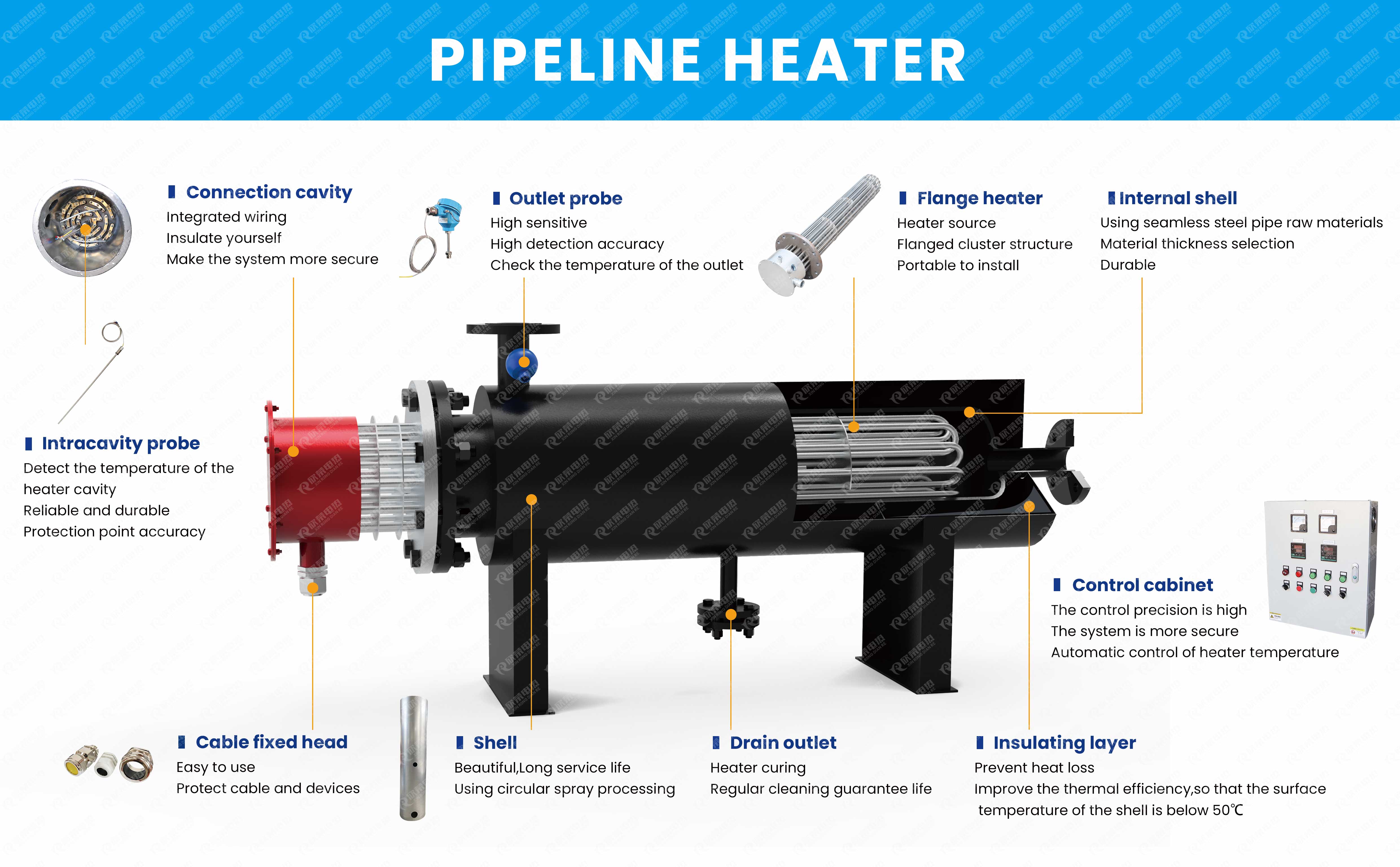

Isimiso sokusebenza se-heater yepayipi elingaqhumi sisekelwe kakhulu ohlelweni lokuguqula amandla kagesi abe ukushisa. Ngokuqondile, i-heater kagesi iqukethe isici sokushisa kagesi, ngokuvamile intambo yokumelana nokushisa okuphezulu, eshisa lapho i-current idlula, futhi ukushisa okubangelwayo kudluliselwa ku-fluid medium, ngaleyo ndlela kushise uketshezi.

I-heater kagesi iphinde ifakwe uhlelo lokulawula, okuhlanganisa izinzwa zokushisa, izilawuli zokushisa zedijithali kanye ne-solid-state relays, okuhlangene kwakha isilinganiso, i-loop yokulawula kanye nokulawula. Inzwa yezinga lokushisa ithola izinga lokushisa lokukhipha uketshezi futhi idlulisele isignali kusilawuli sezinga lokushisa ledijithali, esilungisa okukhiphayo kwe-solid state relay ngokwenani lokushisa elimisiwe, bese lilawula amandla we-heater kagesi ukuze kugcinwe ukuzinza kwezinga lokushisa kwendawo ewuketshezi.

Ngaphezu kwalokho, i-heater kagesi ingase futhi ifakwe idivayisi yokuvikela ukushisa ngokweqile ukuvimbela isici sokushisa ekushiseni ngokweqile, ukugwema ukuwohloka okuphakathi nendawo noma ukulimala kwemishini ngenxa yokushisa okuphezulu, ngaleyo ndlela kuthuthukiswe ukuphepha nokuphila kwemishini.

Imininingwane yomkhiqizo iyaboniswa

Uhlolojikelele lwesicelo sesimo sokusebenza

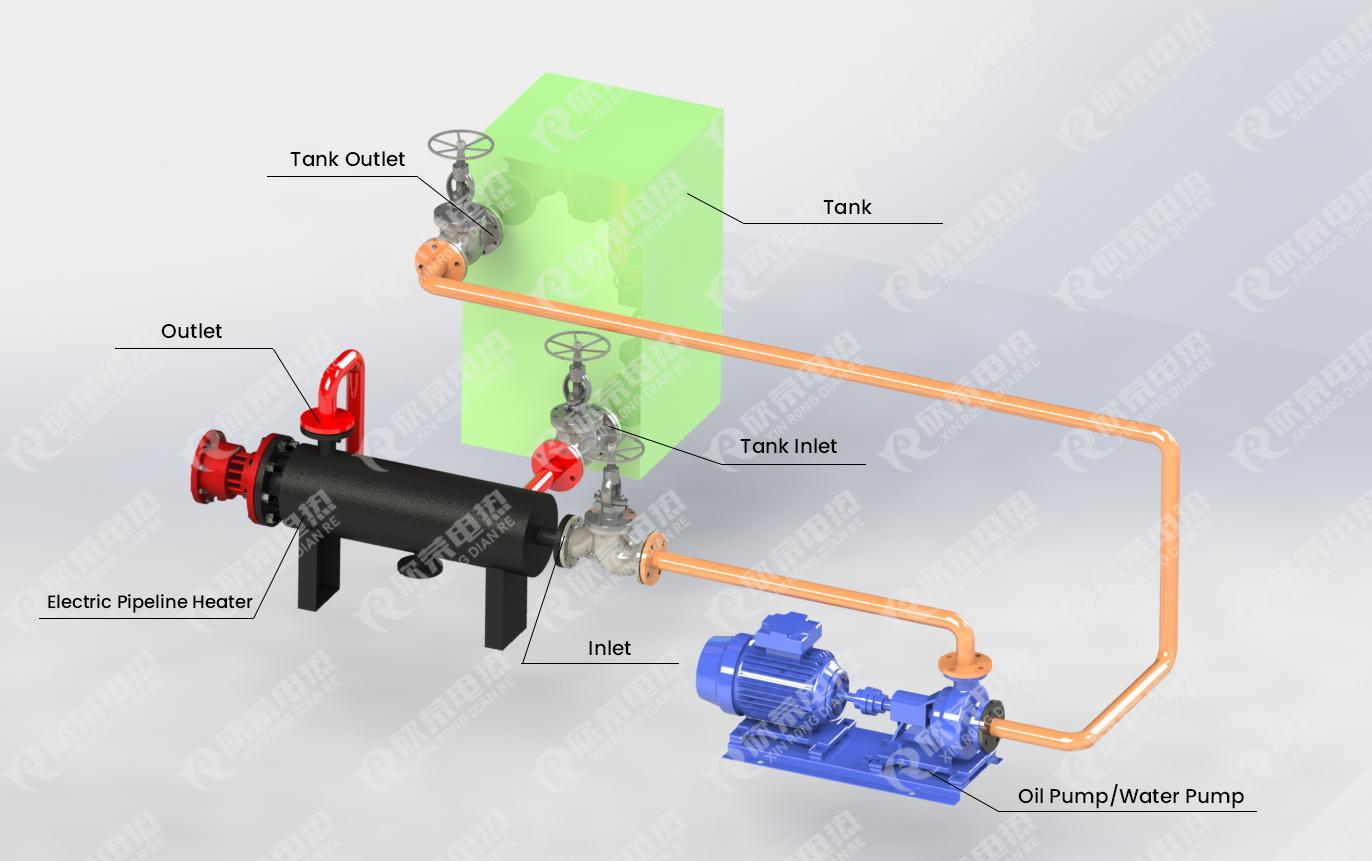

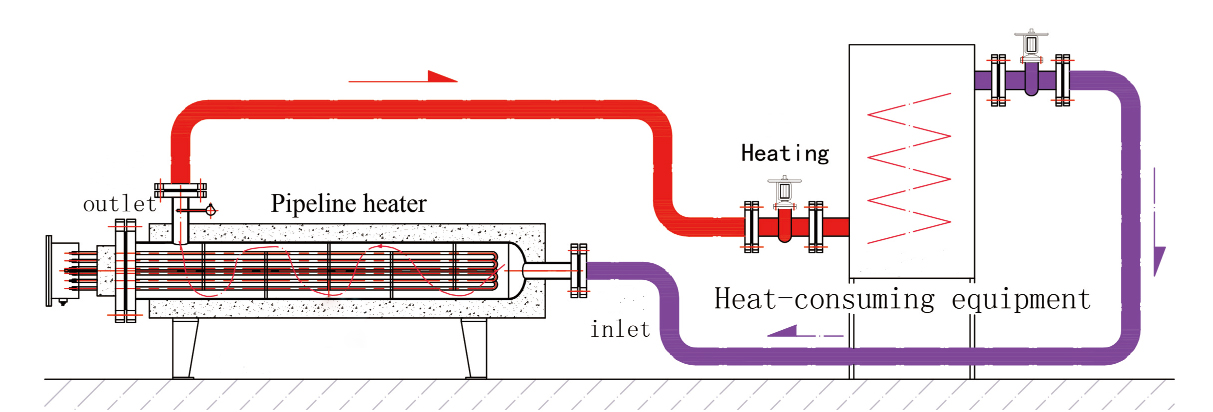

Isimiso sokusebenza sethangi lamanzi elijikeleza isifudumezi sikagesi sisekelwe ikakhulukazi enqubweni yokuguqula amandla kagesi abe amandla okushisa. Ikakhulukazi, ngokuvamile zihlanganisa izingxenye ezibalulekile ezilandelayo:

Isici sokushisa. Ukuguqula amandla kagesi abe ukushisa, lezi zakhi zokushisisa zingacwiliswa emanzini noma zijikeleze ukushisa nge-heater kagesi eshubhu.

Uhlelo lokujikeleza kwegazi. Kufaka phakathi iphampu yokuphoqa amanzi ngento yokushisisa. Phakathi nenqubo yokushisisa, amanzi ampontshelwa ekamelweni lokushisa, ageleze endaweni yokushisa, bese ephuma aye komunye umkhawulo wethangi, enze umjikelezo.

Isistimu yokulawula izinga lokushisa. Lawula ngokuzenzakalelayo izinga lokushisa le-heater ukuze uqinisekise ukuthi izinga lokushisa lamanzi aliphezulu kakhulu noma aliphansi kakhulu. Ilungisa ngokuzenzakalelayo i-heater ukuze iqale futhi ime ngokuvumelana nezinga lokushisa lamanzi ukuze igcine izinga lokushisa elimisiwe.

Lawa madivaysi asetshenziswa kakhulu ezinhlelweni ezidinga ukulawulwa okunembile kwezinga lokushisa lamanzi, njengokuphakelwa kwamanzi ashisayo echibini lethangi, ukufudumeza kwamanzi ezimbonini, njll.

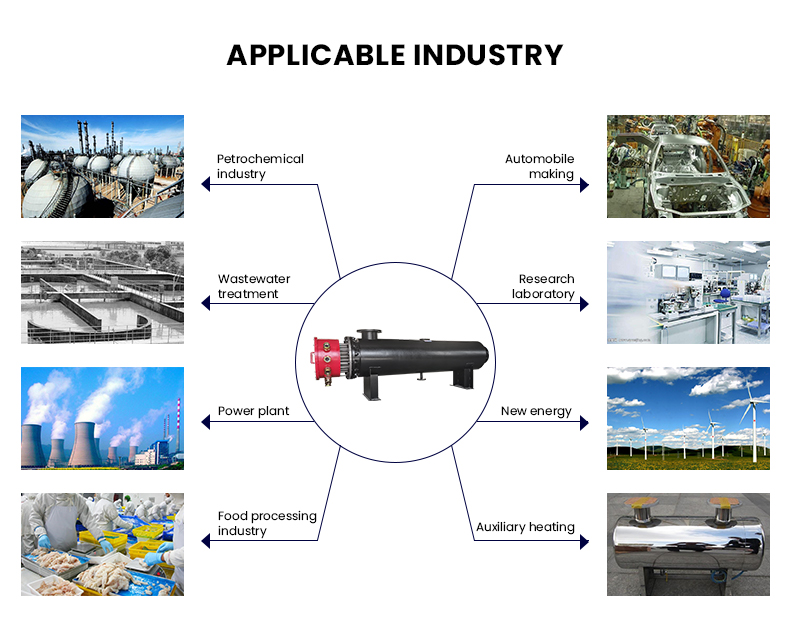

Isicelo somkhiqizo

I-heater yamapayipi isetshenziswa kabanzi ku-aerospace, embonini yezikhali, embonini yamakhemikhali nasemakolishi nasemanyuvesi kanye nezinye ilabhorethri yocwaningo nokukhiqiza eminingi yesayensi. Ifaneleka ngokukhethekile ukulawulwa kwezinga lokushisa okuzenzakalelayo kanye nokugeleza okukhulu kokushisa okuphezulu okuhlanganisiwe uhlelo kanye nokuhlolwa kwesesekeli, indawo yokushisa yomkhiqizo ayi-conductive, ayishisi, ayiqhumi, ayikho ukugqwala kwamakhemikhali, akukho ukungcola, iphephile futhi inokwethenjelwa, futhi indawo yokushisa iyashesha (siyalawuleka).

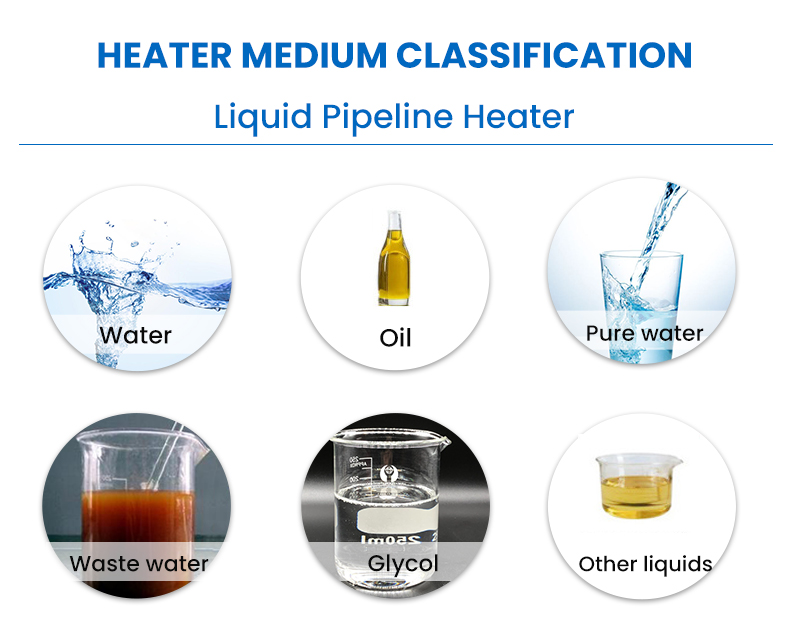

Ukuhlukaniswa kwe-heater medium

Icala lokusebenzisa ikhasimende

Umsebenzi omuhle, ukuqinisekiswa kwekhwalithi

Sithembekile, singochwepheshe futhi siyaphikelela, ukukulethela imikhiqizo emihle kakhulu kanye nenkonzo yekhwalithi.

Sicela uzizwe ukhululekile ukusikhetha, masifakazele amandla ekhwalithi ndawonye.

Isitifiketi kanye neziqu

Ukupakishwa komkhiqizo kanye nokuhamba

Ukupakishwa kwezisetshenziswa

1) Ukupakisha emacaleni okhuni angenisiwe

2) Ithreyi ingenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende

Ukuthuthwa kwempahla

1) Express (isampula oda) noma ulwandle (oda ngobuningi)

2) Izinsizakalo zokuthumela emhlabeni wonke