I-steam pipeline heater kagesi

Isimiso sokusebenza

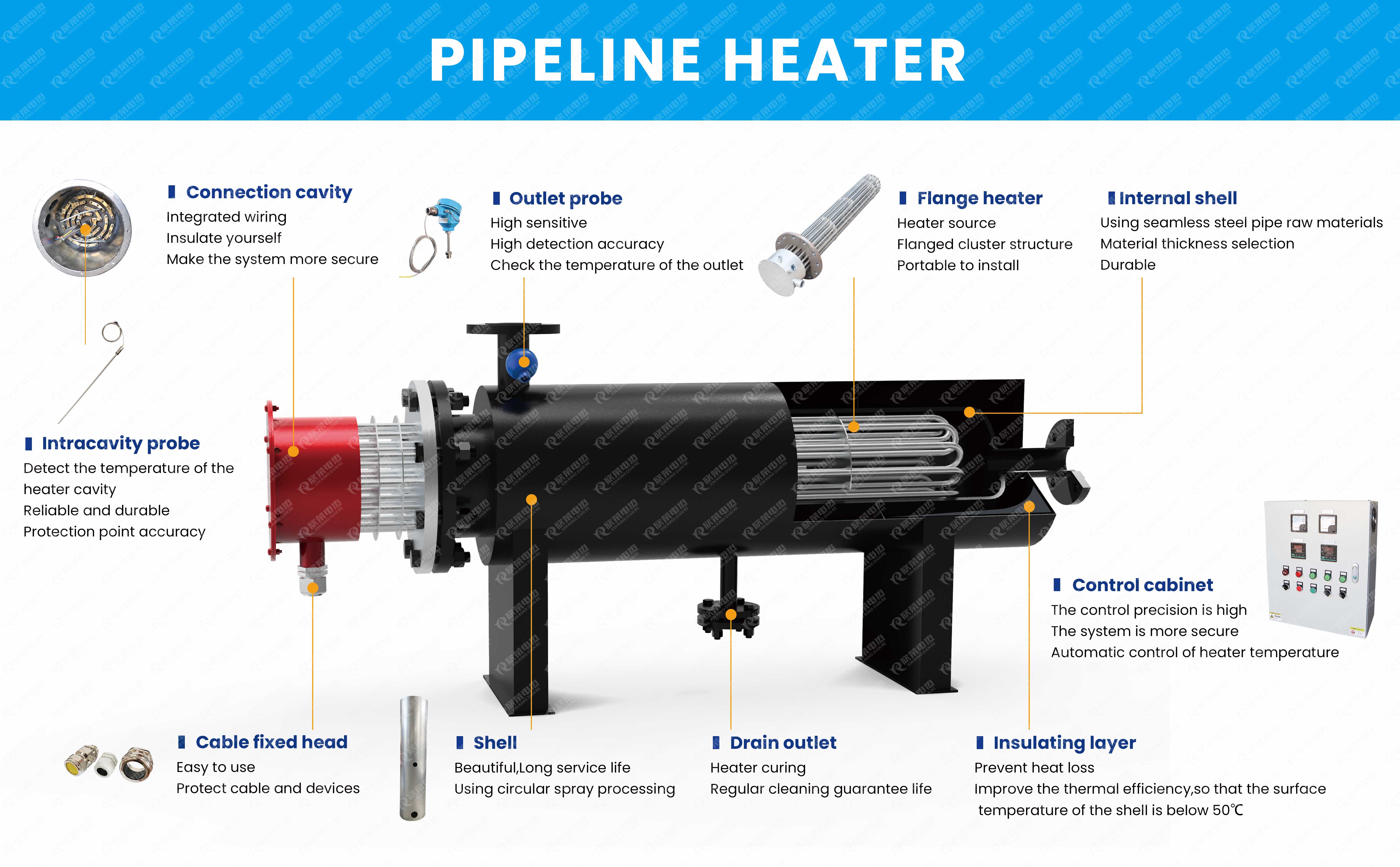

Isici sokushisa sikagesi sikhiqiza ukushisa: Isici sokushisa sikagesi ku-heater siyingxenye eyinhloko yokukhiqiza ukushisa. Lapho amandla kagesi edlula kulezi zakhi, akhiqiza ukushisa okukhulu.

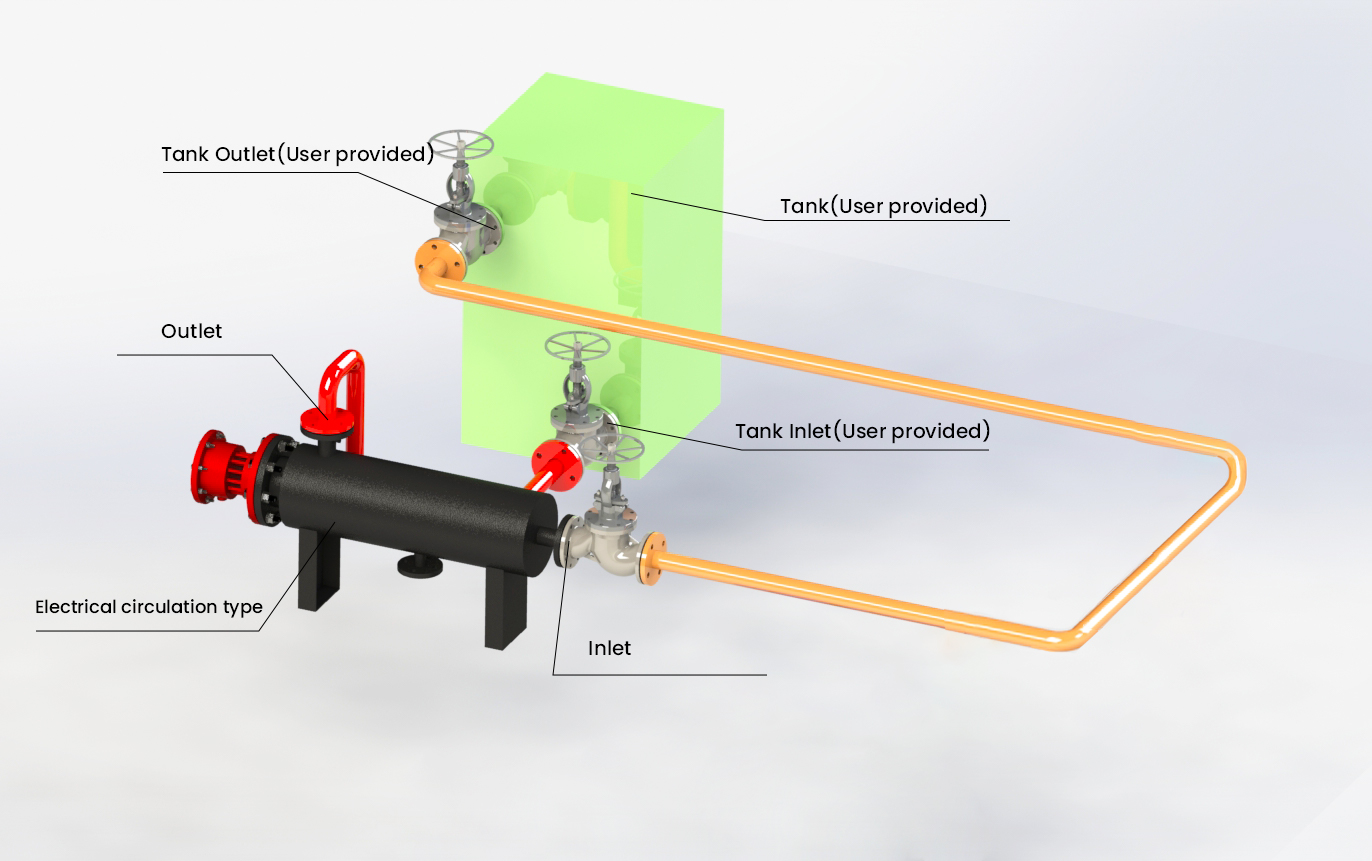

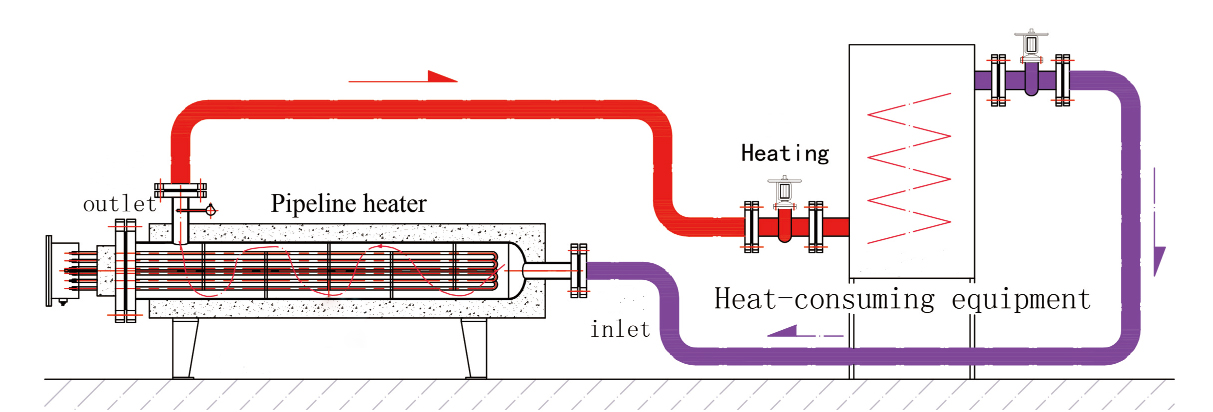

Ukushisisa okuphoqiwe kwe-convection: Uma i-nitrogen noma enye into ephakathi idlula ku-heater, iphampu isetshenziselwa ukuphoqelela i-convection, ukuze okuphakathi kugeleze futhi kudlule endaweni yokushisisa. Ngale ndlela, i-medium, njengesithwali sokushisa, ingakwazi ukudonsa ngokuphumelelayo ukushisa futhi idlulisele ohlelweni oludinga ukushiswa.

Ukulawula izinga lokushisa: I-heater ifakwe isistimu yokulawula ehlanganisa inzwa yokushisa nesilawuli se-PID. Lezi zingxenye zisebenza ndawonye ukuze zilungise ngokuzenzakalelayo amandla okukhishwa kwe-heater ngokuvumelana nezinga lokushisa eliphumayo, ukuqinisekisa ukuthi izinga lokushisa eliphakathi lizinzile ngenani elimisiwe.

Ukuvikela ukushisa ngokweqile: Ukuze uvimbele ukulimala kokushisa okweqile kusici sokushisa, i-heater nayo ifakwe izinto zokuvikela ukushisa ngokweqile. Ngokushesha lapho kutholakala ukushisa ngokweqile, idivayisi inqamula ngokushesha ukunikezwa kwamandla, ivikela isici sokushisa kanye nesistimu.

Imininingwane yomkhiqizo iyaboniswa

Inzuzo yomkhiqizo

I-1, i-medium ingashiswa ekushiseni okuphezulu kakhulu, kuze kufike ku-850 ° C, izinga lokushisa legobolondo lingaba ngu-50 ° C kuphela;

2, ukusebenza kahle okuphezulu: kufika ku-0.9 noma ngaphezulu;

3, izinga lokushisa nokupholisa liyashesha, lifika ku-10℃/S, inqubo yokulungisa iyashesha futhi izinzile. Ngeke kube khona ukuhola kwezinga lokushisa kanye ne-lag phenomenon ye-medium elawulwayo, okuzobangela ukukhukhuleka kokushisa kokulawula, okulungele ukulawula okuzenzakalelayo;

I-4, izakhiwo ezinhle zemishini: ngoba umzimba wayo wokushisa uyisisetshenziswa esikhethekile se-alloy, ngakho-ke ngaphansi komthelela wokugeleza komoya ocindezelayo, kungcono kunanoma yiziphi izakhiwo zomshini wokushisa womzimba namandla, okudinga isikhathi eside esiqhubekayo sokushisa komoya kanye nokuhlolwa kwezesekeli kunenzuzo enkulu;

5. Uma ingaphuli inqubo yokusebenzisa, impilo ingaba yinde amashumi eminyaka ambalwa, ehlala isikhathi eside;

6, umoya ohlanzekile, usayizi omncane;

I-7, i-heater yepayipi ingaklanywa ngokuya ngezidingo zabasebenzisi, izinhlobo eziningi zama-heater kagesi omoya.

Uhlolojikelele lwesicelo sesimo sokusebenza

Ukushisisa okwesibili Izifudumezi zikagesi zisetshenziselwa ukushisisa kabusha isitimu ukuze kukhuphule izinga lokushisa laso ngemva kokuba sesenziwe kakade.

Lokhu kuvame ukufezwa ngokungeza i-heater kagesi ekupheleni kwepayipi le-steam ukuze kuqinisekiswe ukuthi izinga lokushisa le-radiator ekupheleni kwepayipi lifinyelela inani elibekiwe, ngaleyo ndlela kwandiswe umphumela wokushisa wesikhala noma ukufeza izinga lokushisa le-steam elidingekayo kumshini oshisayo wokugcina, futhi inqubo yokushisa ayishintshi ukucindezela kwesitimu endaweni yokuphuma.

Ngenxa yokungaqini kokugeleza kwe-steam medium, ukulawula kuvame ukulawulwa ukunemba kwe-thyristor ukuze kuqinisekiswe ukuzinza kwezinga lokushisa le-steam ye-outlet.

Kafushane, umgomo wokusebenza we-steam yesibili yokufudumeza kagesi kagesi uhilela inqubo yokuguqula amandla kagesi abe amandla okushisa, ukulawula ngokunembile ukukhiqizwa kwesitimu kanye nokushisa kwesibili ngohlelo lokulawula okuzenzakalelayo, kanye nokuklanywa kwesistimu yokuvikela ukuphepha, ukuze kuqinisekiswe ukusebenza kwayo okuphumelelayo nokuphephile.

Isicelo somkhiqizo

I-heater yamapayipi isetshenziswa kakhulu endaweni yasemkhathini, embonini yezikhali, embonini yamakhemikhali nasemakolishi nasemanyuvesi nakweminye ilabhorethri eminingi yocwaningo nokukhiqiza yesayensi. Ifaneleka ngokukhethekile ukulawulwa kwezinga lokushisa okuzenzakalelayo kanye nokugeleza okukhulu kokushisa okuphezulu okuhlanganisiwe uhlelo kanye nokuhlolwa kwesesekeli, indawo yokushisa yomkhiqizo ayi-conductive, ayishisi, ayiqhumi, ayikho ukugqwala kwamakhemikhali, akukho ukungcola, iphephile futhi inokwethenjelwa, futhi indawo yokushisa iyashesha (siyalawuleka).

Icala lokusebenzisa ikhasimende

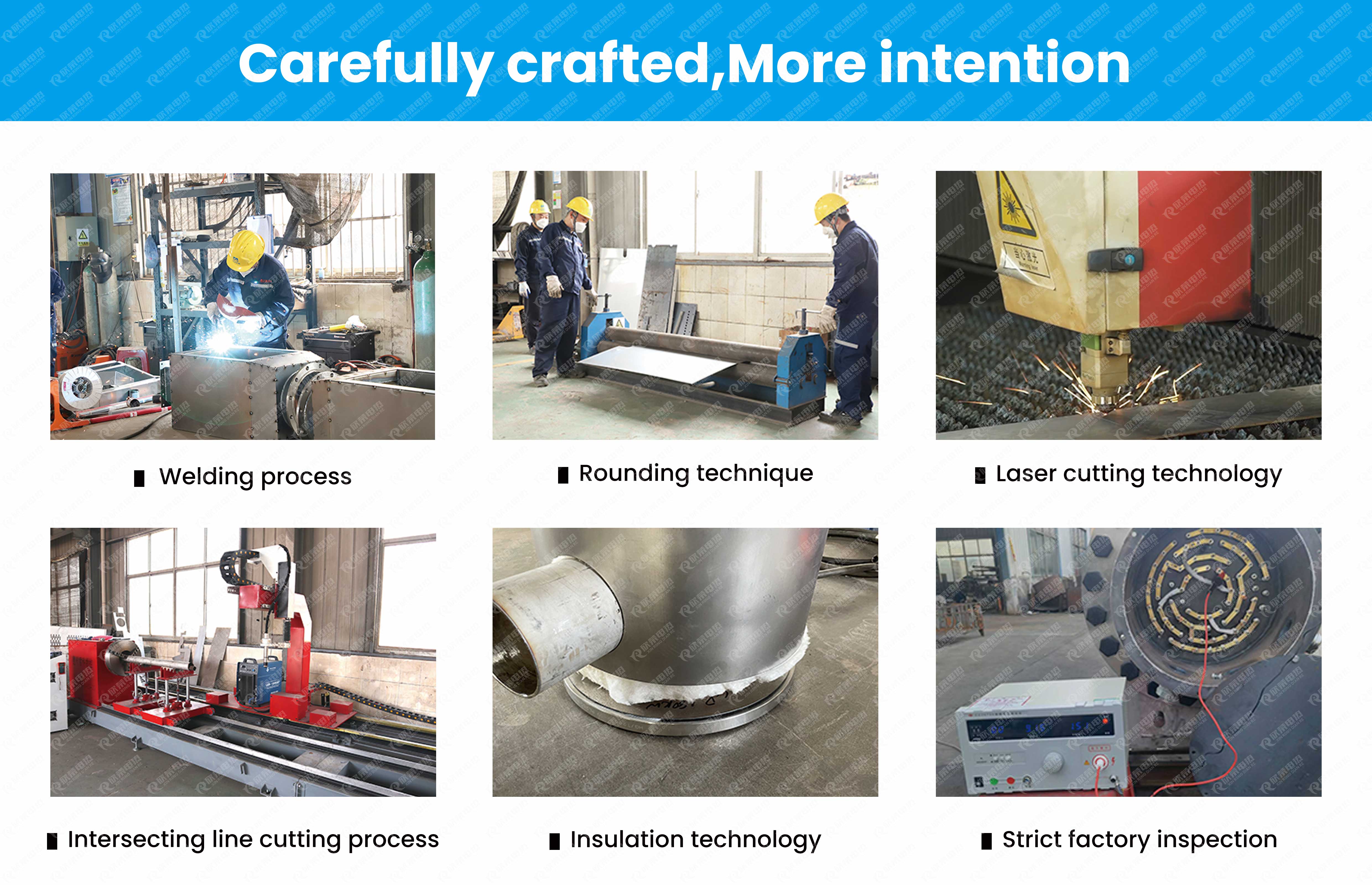

Umsebenzi omuhle, ukuqinisekiswa kwekhwalithi

Sithembekile, singochwepheshe futhi siyaphikelela, ukukulethela imikhiqizo emihle kakhulu kanye nenkonzo yekhwalithi.

Sicela uzizwe ukhululekile ukusikhetha, masifakazele amandla ekhwalithi ndawonye.

Isitifiketi kanye neziqu

Ukupakishwa komkhiqizo kanye nokuhamba

Ukupakishwa kwezisetshenziswa

1) Ukupakisha emacaleni okhuni angenisiwe

2) Ithreyi ingenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende

Ukuthuthwa kwempahla

1) Express (isampula oda) noma ulwandle (oda ngobuningi)

2) Izinsizakalo zokuthumela emhlabeni wonke