I-heater kawoyela yepayipi

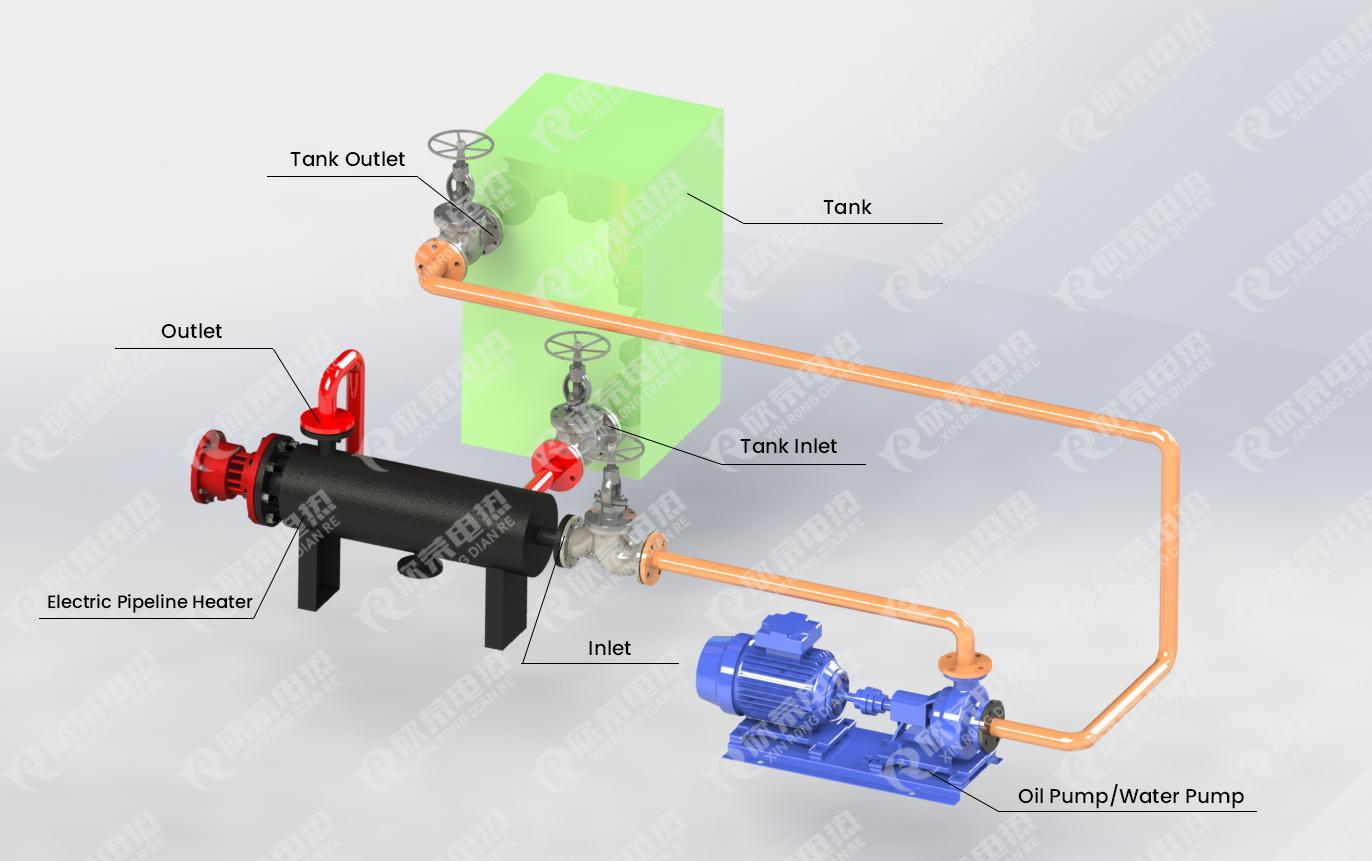

Isimiso sokusebenza

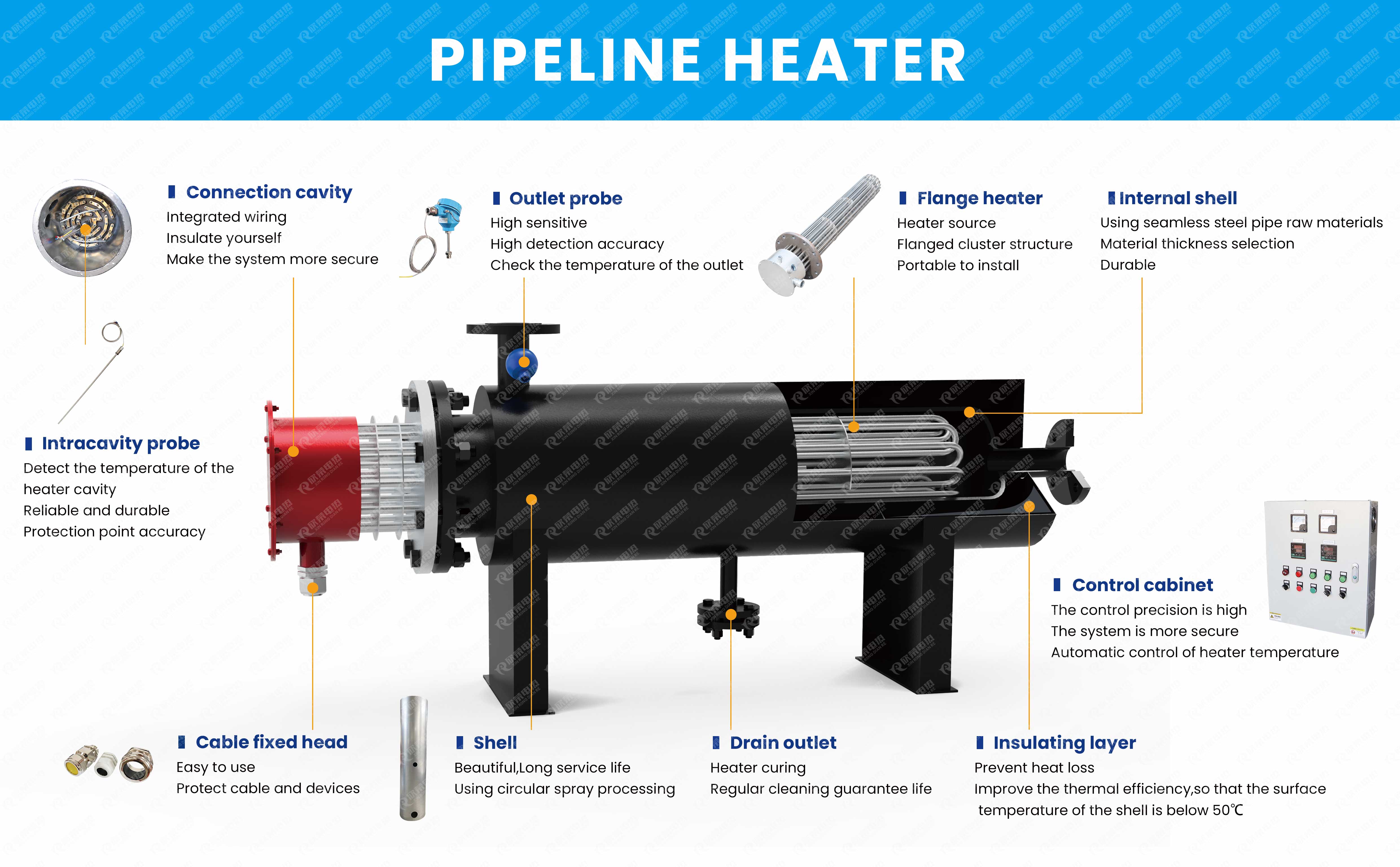

Isimiso sokushisisa uwoyela wepayipi sisekelwe kakhulu ohlelweni lokuguqula amandla kagesi abe ukushisa. Ngokuqondile, i-heater kagesi iqukethe isici sokushisa kagesi, ngokuvamile intambo yokumelana nokushisa okuphezulu, eshisa lapho i-current idlula, futhi ukushisa okubangelwayo kudluliselwa ku-fluid medium, ngaleyo ndlela kushise uketshezi.

I-heater kagesi iphinde ifakwe uhlelo lokulawula, okuhlanganisa izinzwa zokushisa, izilawuli zokushisa zedijithali kanye ne-solid-state relays, okuhlangene kwakha isilinganiso, i-loop yokulawula kanye nokulawula. Inzwa yezinga lokushisa ithola izinga lokushisa lokukhipha uketshezi futhi idlulisele isignali kusilawuli sezinga lokushisa ledijithali, esilungisa okukhiphayo kwe-solid state relay ngokwenani lokushisa elimisiwe, bese lilawula amandla we-heater kagesi ukuze kugcinwe ukuzinza kwezinga lokushisa kwendawo ewuketshezi.

Ngaphezu kwalokho, i-heater kagesi ingase futhi ifakwe idivayisi yokuvikela ukushisa ngokweqile ukuvimbela isici sokushisa ekushiseni ngokweqile, ukugwema ukuwohloka okuphakathi nendawo noma ukulimala kwemishini ngenxa yokushisa okuphezulu, ngaleyo ndlela kuthuthukiswe ukuphepha nokuphila kwemishini.

Imininingwane yomkhiqizo iyaboniswa

Uhlolojikelele lwesicelo sesimo sokusebenza

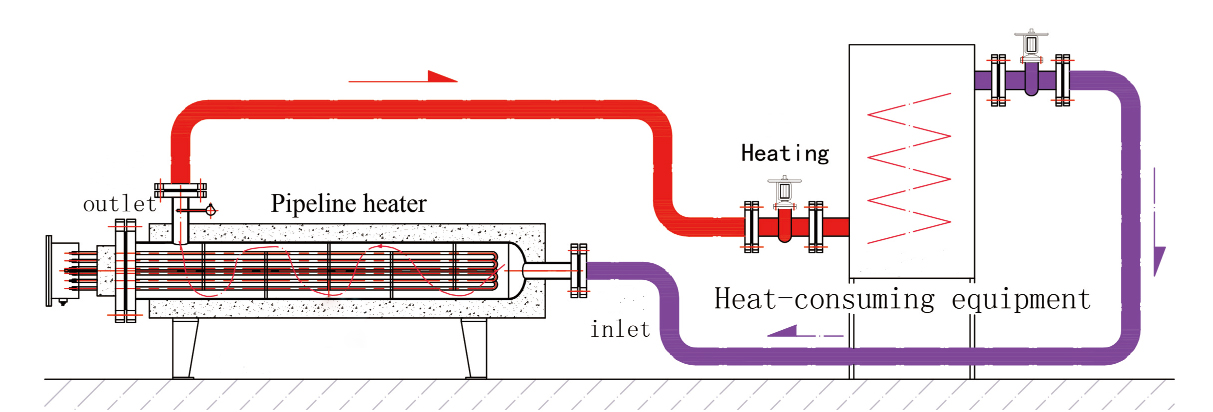

Isimiso sokusebenza se-heater kagesi yamafutha ngokuyinhloko sisekelwe ekushiseni okukhiqizwa yisici sokushisa kagesi, esidluliselwa emafutheni ashisayo, ukuze izinga lokushisa liphakanyiswe, bese ukushisa kudluliselwa kumishini noma inqubo edinga ukushiswa ngokusebenzisa ukujikeleza kwesigaba se-liquid. Ireferensi eqondile ingaba kanjena:

Isici sokushisisa sikhiqiza ukushisa. Izinto zokushisisa ngogesi (njengamashubhu okushisa kagesi noma izinduku zokushisisa) zikhiqiza ukushisa uma zinikwe amandla.

Amafutha ashisayo adlulisa ukushisa. Isici sokushisa sidlulisela ukushisa emafutheni ashisayo ku-tubing, futhi izinga lokushisa lamafutha ashisayo liyakhuphuka ngemva kokushiswa.

Uhlelo lokulawula izinga lokushisa lulawula umsinga. Isistimu yokulawula izinga lokushisa ithola izinga lokushisa lamafutha ashisayo ngesikhathi sangempela ngenzwa, futhi ilungisa okwamanje ngokuvumelana nezinga lokushisa esethiwe, lilawula isimo sokusebenza sesici sokushisa, futhi igcina izinga lokushisa lamafutha ashisayo lizinzile.

Amafutha okushisa okushisa ajikeleza ukudluliswa kokushisa. Amafutha ashisayo ashisayo ajikeleza ohlelweni ngokusebenzisa ipompo ejikelezayo, edlulisela ukushisa emshinini oshisayo, futhi ngemva kokushisa kukhishwa imishini yokushisa, amafutha ashisayo abuyela ku-heater ukuze ashiswe kabusha.

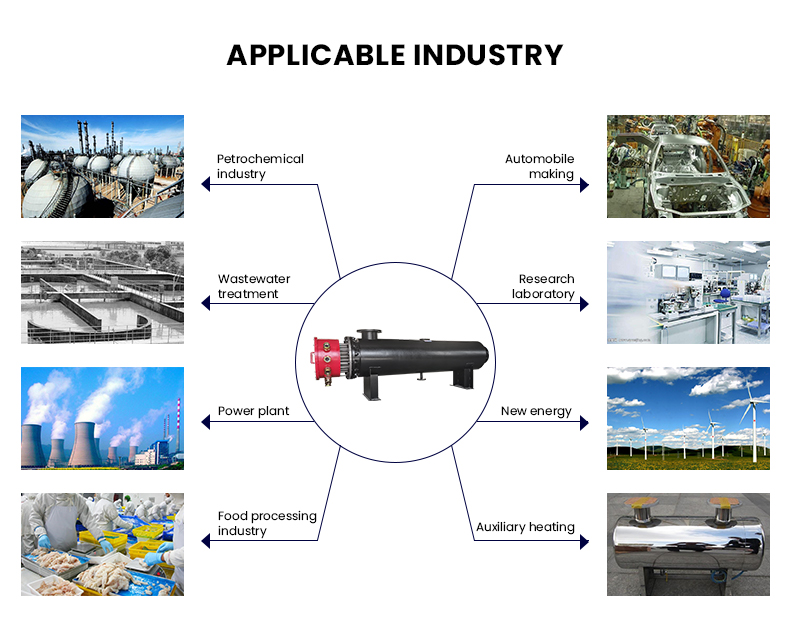

Isicelo somkhiqizo

I-heater yamapayipi isetshenziswa kabanzi ku-aerospace, embonini yezikhali, embonini yamakhemikhali nasemakolishi nasemanyuvesi kanye nezinye ilabhorethri yocwaningo nokukhiqiza eminingi yesayensi. Ifaneleka ngokukhethekile ukulawulwa kwezinga lokushisa okuzenzakalelayo kanye nokugeleza okukhulu kokushisa okuphezulu okuhlanganisiwe uhlelo kanye nokuhlolwa kwesesekeli, indawo yokushisa yomkhiqizo ayi-conductive, ayishisi, ayiqhumi, ayikho ukugqwala kwamakhemikhali, akukho ukungcola, iphephile futhi inokwethenjelwa, futhi indawo yokushisa iyashesha (siyalawuleka).

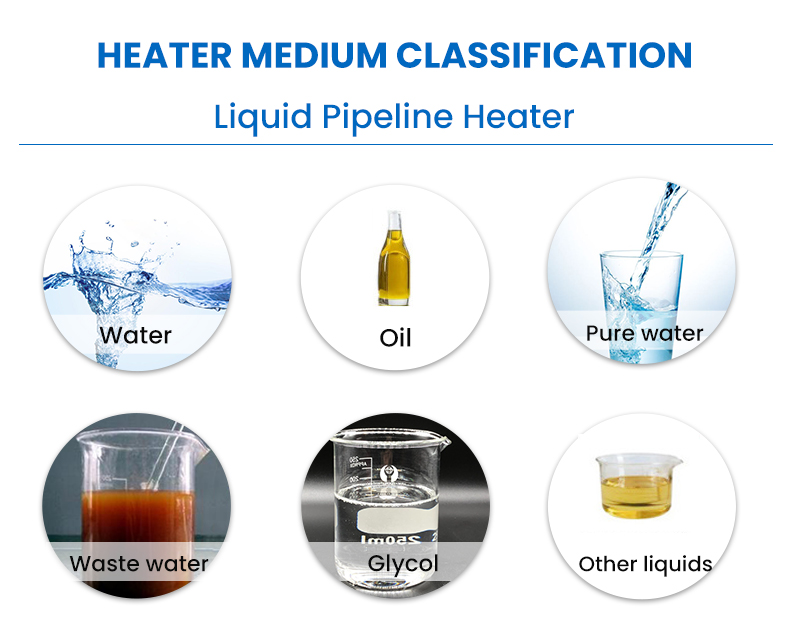

Ukuhlukaniswa kwe-heater medium

Icala lokusebenzisa ikhasimende

Umsebenzi omuhle, ukuqinisekiswa kwekhwalithi

Sithembekile, singochwepheshe futhi siyaphikelela, ukukulethela imikhiqizo emihle kakhulu kanye nenkonzo yekhwalithi.

Sicela uzizwe ukhululekile ukusikhetha, masifakazele amandla ekhwalithi ndawonye.

Isitifiketi kanye neziqu

Ukupakishwa komkhiqizo kanye nokuhamba

Ukupakishwa kwezisetshenziswa

1) Ukupakisha emacaleni okhuni angenisiwe

2) Ithreyi ingenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende

Ukuthuthwa kwempahla

1) Express (isampula oda) noma ulwandle (oda ngobuningi)

2) Izinsizakalo zokuthumela emhlabeni wonke