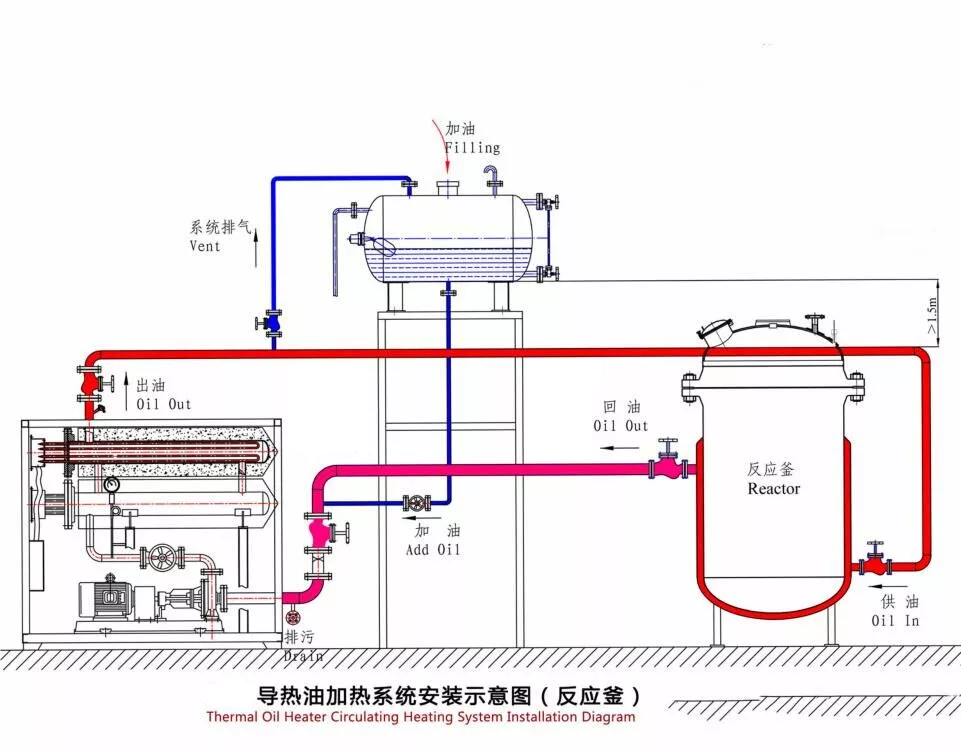

Ngesithando somlilo sikawoyela oshisayo, uwoyela oshisayo ujovwa ohlelweni ngokusebenzisa i- ithangi lokunweba, futhi i-inlet yesithando sokushisa amafutha ashisayo iphoqeleka ukuba ijikeleze ngepompo yamafutha ekhanda eliphezulu. I-oil inlet kanye ne-oil outlet inikezwa ngokulandelana kwezinto zokusebenza, ezixhunywe ngama-flanges. Ukushisa kukhiqizwa futhi kudluliselwe isici sokushisa sikagesi esicwiliswe emafutheni ahambisa ukushisa. Amafutha aqhuba ukushisa asetshenziswa njengendawo ephakathi kanye nepompo ejikelezayo isetshenziselwa ukuphoqa uwoyela ophethe ukushisa ukuthi ujikeleze esigabeni samanzi. Ngemva kokuba imishini ilayishwe imishini yokushisa, iphinda idlule iphampu ejikelezayo, ibuyele ku-heater, ibambe ukushisa, futhi iyidlulisele kumshini wokushisa. Ngale ndlela, ukudluliswa kokushisa okuqhubekayo kuyabonakala, izinga lokushisa lezinto ezishisayo liyanda, futhi inqubo yokushisa ifinyelelwa.

Ngokusho kwezici zenqubo yeisithando somlilo esishisayo sikagesi sikagesi, isilawuli sokushisa esicacile sedijithali esinembayo sikhethwa ukuze kuqalwe ngokuzenzakalelayo amapharamitha wenqubo alungile wokulawula izinga lokushisa kwe-PID. Isistimu yokulawula iyisistimu yokuphakelayo engemihle yesiyingi esivaliwe. Isignali yezinga lokushisa likawoyela etholwe i-thermocouple idluliselwa kusilawuli se-PID, esishayela isilawuli esingenakuthinta kanye nomjikelezo womsebenzi ophumayo esikhathini esinqunyiwe, ukuze kulawulwe amandla okukhiphayo we-heater futhi kuhlangabezane nezidingo zokushisa.

Isikhathi sokuthumela: Nov-02-2022