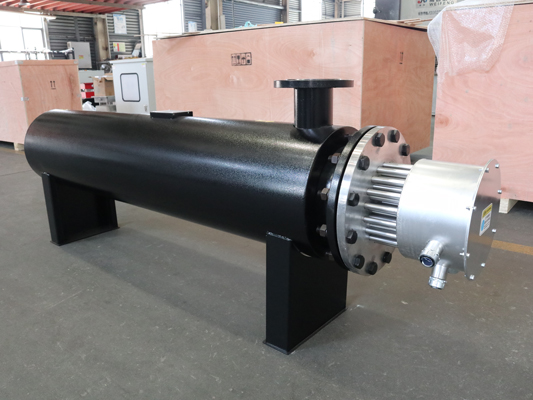

Ii-heater kagesi ye-nitrogen pipeline heateruhlelo iyithuluzi eliguqula amandla kagesi abe amandla ashisayo ukushisisa i-nitrogen egeleza epayipini. Isakhiwo sesistimu yayo idinga ukucabangela ukusebenza kahle kokushisisa, ukuphepha, nokulawula okuzenzakalelayo. Okulandelayo izingxenye zayo eziyinhloko kanye nezincazelo ezinemininingwane:

1,Imodyuli eyinhloko yokushisisa

1. Isici sokushisa sikagesi

• Izingxenye zokushisisa:

Fin type electric heat tube tube: eyenziwe ngensimbi engagqwali (efana ne-304/316L) noma i-high-temperature alloy material, enamaphiko acindezelwe phezulu ukuze kwandiswe indawo yokukhipha ukushisa nokuthuthukisa ukusebenza kahle kokushintshanisa ukushisa. Ingaphakathi lenziwe ngocingo lokumelana (i-nickel chromium alloy), egcwele i-magnesium oxide powder (MgO) njengento evalelayo futhi ebamba ukushisa, iqinisekisa ukufakwa kukagesi nokumelana nokushisa okuphezulu (ukumelana nezinga lokushisa kungafinyelela ku-500 ℃ noma ngaphezulu).

Indlela yokufaka:

Iamashubhu okushisaasatshalaliswa ngokulinganayo ngasendleleni ye-axial yepayipi futhi agxiliswe odongeni olungaphakathi noma umkhono wangaphandle wepayipi ngama-flange noma ama-welding, okuqinisekisa ukuthintana okwanele nendawo yokushisisa lapho i-nitrogen igeleza.

Amasethi amaningi amashubhu okushisa angahlanganiswa ngokuhambisana/uchungechunge, futhi ukulawulwa kwamandla kungafinyelelwa ngokulawula okuhlanganisiwe (njengokushisa kwezigaba ezintathu: amandla aphansi, aphakathi, namandla aphezulu).

2. Umzimba wamapayipi

Ipayipi eliyinhloko:

Impahla: Insimbi engagqwali 304/316L (ikwazi ukumelana nokugqwala kwe-nitrogen), eno-310S noma i-Inconel alloy etholakalayo ezimweni zokushisa okuphezulu.

Isakhiwo: Ukushisela ipayipi lensimbi engenamthungo noma uxhumano lwe-flange, ukwelashwa kokupholisha odongeni lwangaphakathi (Ra ≤ 3.2 μ m) ukunciphisa ukumelana nokugeleza kwegesi, ububanzi bepayipi obuklanywe ngokwezinga lokugeleza kwe-nitrogen (m ³/h) kanye nesivinini sokugeleza (okunconyiwe ngu-5-15m/s), ngokuhambisana ne-GB/T 18914 noma i-ASME ejwayelekile.

• Isendlalelo se-insulation:

Goqa ungqimba lwangaphandle ngoboya betshe noma i-aluminium silicate fiber, enogqinsi luka-50-100mm, bese uyimboza ngepuleti lensimbi engagqwali ukuze unciphise ukulahlekelwa ukushisa (izinga lokushisa elingaphezulu ≤ 50 ℃).

2,Isistimu yokulawula

1. Iyunithi yokulawula izinga lokushisa

• Izinzwa:

Isici sokulinganisa izinga lokushisa: I-Pt100 thermistor (ukunemba ±0.1 ℃) noma i-thermocouple yohlobo lwe-K (ukumelana nezinga lokushisa eliphezulu ≥ 1000 ℃), efakwe endaweni yokungena nokuphuma kwepayipi namaphakathi nengxenye yokushisisa, ukuze kuqashwe izinga lokushisa ngesikhathi sangempela.

Izinzwa zokugeleza/zengcindezi: i-vortex flowmeter, i-thermal mass flowmeter (ukugeleza kokulinganisa), i-pressure transmitter (ingcindezi yokulinganisa), esetshenziselwa ukubala isidingo samandla okushisa.

• Isilawuli:

Isistimu ye-PLC noma i-DCS: I-algorithm ye-PID ehlanganisiwe, ilungisa ngokuzenzakalelayo amandla okushisa ngokuvumelana nezinga lokushisa elimisiwe (njengokulawula amandla e-thyristor noma i-SOD-state relay SSR), isekela ukuqapha okukude nokuqoshwa kwedatha.

2. Imojula yokulawula ugesi

• Isistimu yamandla:

◦ Amandla afakiwe: AC 380V/220V,50Hz,Lungiselela izinqamuli zesekethe nezivikeli ezivuzayo ukuze zisekele ukunikezwa kwamandla okulingana kwezigaba ezintathu.

Ukulawula amandla: I-Solid state relay (SSR) noma isilawuli samandla, ukushintsha ngaphandle kokuthinta, isivinini sokuphendula esisheshayo, impilo ende.

• Idivayisi yokuvikela ukuphepha:

Ukuvikela izinga lokushisa elingaphezu kokushisa: Ifakwe i-thermostat ye-bimetallic eyakhelwe ngaphakathi noma ukushintsha kwezinga lokushisa, lapho izinga lokushisa elilinganisiwe lidlula inani elibekiwe (elifana no-20 ℃ ngaphezu kwezinga lokushisa eliqondiwe), ukunikezwa kwamandla okushisisa kuvalwa ngenkani futhi i-alamu iyacushwa.

Ukuvikelwa kwesekethe okwedlulele/okufushane: i-transformer yamanje+i-circuit breaker ukuvikela ukungahambi kahle kwesekethe okubangelwa amaphutha eshubhu lokushisa.

Ukuvikela ingcindezi: Iswishi yokucindezela ixhunywe ukuze ivaleke ukuze kuvinjelwe ukucindezela kwepayipi (okuqaliswa lapho lidlula izikhathi ezingu-1.1 kunomfutho wedizayini).

Umsebenzi wokuxhumanisa: Kuxhunywe nomthombo we-nitrogen, ukushisisa akuvunyelwe uma igesi ingekho ukugwema ukusha okomile.

3,Izingxenye ezisizayo

1. Xhuma futhi ufake izingxenye

Ama-flange okungenisa nokuthekelisa: Ama-flange ayisicaba e-RF (PN10/PN16) asetshenziswa, anento efanayo neyepayipi, futhi i-gasket evalayo iyigasket esongwe ngensimbi noma i-PTFE gasket.

• Abakaki nezingxenye zokulungisa: Insimbi ye-Carbon steel galvanized noma insimbi engagqwali ubakaki, osekela ukufakwa okuvundlile/kuqondile, nesikhala esiklanywe ngokuya ngobubanzi bepayipi namandla okuthwala umthwalo (njengesikhala se-DN50 sikabakaki wamapayipi ≤ 3m).

2. Ukuhlola kanye nokugcinwa interface

Isixhumi esibonakalayo sokulinganisa izinga lokushisa/ukucindezela: Gcina i-G1/2 "noma i-NPT1/2" yokuxhumana enentambo endaweni yokungena nokuphumayo kwepayipi ukuze kuhlakazwe kalula kanye nokulinganiswa kwezinzwa.

• Indawo yokukhipha amanzi: Ivalvu yokukhipha i-DN20 ifakwa ngaphansi kwepayipi ukuze kukhishwe njalo amanzi ajiyile noma ukungcola (uma i-nitrogen iqukethe amanani ambalwa omswakamo).

• Imbobo yokuhlola: Amapayipi amade noma izakhiwo eziyinkimbinkimbi zifakwe amaflantshi okuhlola okuvuleka ngokushesha ukuze kufakwe amapayipi okufudumeza kalula nokuhlanzwa kwezindonga zangaphakathi.

4,Ukuphepha kanye Nomklamo wokufakazela ukuqhuma (uma kudingeka)

Isilinganiso sobufakazi bokuqhuma: Uma sisetshenziswa ezindaweni ezivutha umlilo neziqhumayo (njengama-workshops e-petrochemical), isistimu kufanele ihambisane ne-Ex d IICT6-proof-proof standard, ishubhu lokufudumeza kufanele lingaqhumi (linesitifiketi sokuvikela ukuqhuma samabhokisi ahlanganayo), futhi izingxenye zikagesi kufanele zifakwe emakhabetheni okulawula ukuqhuma.

Isivikelo somhlaba: Lonke isistimu isekelwe ngokuthembekile (ukumelana nesisekelo ≤ 4 Ω) ukuvimbela ukunqwabelana kukagesi omile kanye nobungozi bokuvuza.

5,Izinhlelo zokusebenza ezijwayelekile

Imboni yamakhemikhali: ukuhlanzwa kwe-nitrogen, ukushisa kwe-reactor, inqubo yokomisa ukushisa.

Imboni yezogesi: Ukushisisa initrogen emsulwa ekukhiqizeni ama-semiconductor (kudinga ukupholishwa kwangaphakathi kodonga ukuze kugwenywe ukungcoliswa).

I-Metallurgy/Ukwelashwa Kokushisa: Ukushisisa indawo yokungena kwesithando somlilo, ukuthungathwa kwensimbi ngokushisisa okuyisivikelo.

finyeza

Ii-heater kagesi ye-nitrogen pipeline heaterisistimu igxile ezintweni zokushisisa zikagesi futhi ifinyelela izinga lokushisa elinembile ngokulawula okuhlakaniphile. Isakhiwo sayo sidinga ukulinganisa ukusebenza kahle kokushisayo, ukuphepha, kanye nokwenza kahle koketshezi, okulenze lifaneleke izimo zezimboni ezidinga izinga lokushisa, ukuhlanzeka, nokuvimbela ukuqhuma. Lapho uklama, izinto zokwakha, ukumiswa kwamandla, kanye nezinhlelo zokulawula kufanele zikhethwe ngokusekelwe ezimweni ezithile zokusebenza (izinga lokugeleza, izinga lokushisa, ingcindezi, indawo ezungezile) ukuze kuqinisekiswe ukusebenza okuzinzile kwesikhathi eside.

Uma ufuna ukwazi okwengeziwe ngomkhiqizo wethu, sicelaXhumana nathi!

Isikhathi sokuthumela: Apr-10-2025