1. Inqubo yokusebenza kanye nesimiso

Iisithando somlilo samafutha okushisa kagesi ngokuyinhloko iguqula amandla kagesi abe amandla ashisayo ngokusebenzisaizakhi zokushisa zikagesi(njengamashubhu okushisa kagesi). Lezi zakhi zokushisa zikagesi zifakwe ngaphakathi kwekamelo lokushisa lesithando somlilo esishisayo. Uma amandla evuliwe, amafutha okudlulisa ukushisa azungeze isici sokushisa abamba ukushisa futhi izinga lokushisa liyenyuka. Amafutha okushisa okushisa ahanjiswa ejazini noma ikhoyili yomkhumbi wokusabela ngepompo yokujikeleza. Ukushisa kudluliselwa ezintweni ezingaphakathi kwe-reactor ngokusebenzisa i-thermal conduction, okwenza izinga lokushisa lezinto likhuphuke futhi liqedele inqubo yokushisa. Ngemva kwalokho, amafutha okudlulisa ukushisa anezinga lokushisa elincishisiwe azobuyela esithandweni sokushisa sikagesi sokudlulisa ukushisa ukuze ashiswe kabusha, futhi lo mjikelezo uzoqhubeka nokuhlinzeka ngokushisa ku-kettle yokusabela.

2. Izinzuzo:

Ihlanzekile futhi inobungani nemvelo: Isithando sokushisa sikagesi esishisayo sokudlulisa ukushisa ngeke sikhiqize igesi yokukhipha umlilo ngesikhathi sokusebenza, okuzuzisa kakhulu kwezinye izindawo ezinezidingo zekhwalithi ephezulu yomoya, njengamalabhorethri, izindawo zokusebenzela ezihlanzekile, kanye nokufudumeza kweketela lokusabela. Isibonelo, kumalabhorethri ocwaningo nokuthuthukiswa kwezinkampani ezenza imithi, ukusetshenziswa kweziko likawoyela ashisisa ngogesi kungagwema ukuphazamiseka kwemikhiqizo evuthayo ekuhlaziyeni ukwakheka kwezidakamizwa kanye nokusabela kokuhlanganiswa, futhi ngeke kukhiqize amagesi abamba ukushisa namagesi ayingozi njenge-carbon dioxide ne-sulphur dioxide, ehlangabezana nezidingo zokuvikela imvelo.

Ukulawulwa kwezinga lokushisa okunembe kakhulu: Ukushisisa ngogesi kungafinyelela ukulawulwa kwezinga lokushisa okunembe kakhudlwana. Ngamathuluzi okulawula izinga lokushisa athuthukisiwe, izinga lokushisa likawoyela wokudlulisa ukushisa lingalawulwa phakathi kwebanga elincane kakhulu lokuguquguquka, ngokuvamile kuzuzwe ukunemba± 1 ℃noma ngaphezulu. Ekushisiseni imikhumbi yokusabela emkhakheni wobunjiniyela bamakhemikhali amahle, ukulawulwa kwezinga lokushisa okunembe kakhulu kubalulekile ukuze kuqinisekiswe ukungaguquguquki kwekhwalithi nokusebenza komkhiqizo.

Ukufakwa kalula: Isakhiwo sesithando sokushisa sikagesi sokudlulisa ukushisa silula, futhi asidingi izibasi eziyinkimbinkimbi, izinhlelo zokuhlinzeka ngophethiloli, nezinhlelo zokungenisa umoya njengeziko likawoyela noma igesi yokudlulisa ukushisa kwamafutha. Kwamanye amabhizinisi amancane noma amaphrojekthi okushisa esikhashana anendawo elinganiselwe, ukufakwa kwezithando zokushisa zikagesi ezishisayo eduze kweketela yokusabela kulula kakhulu, kusindisa isikhala esiningi sokufaka nesikhathi.

Ukusebenza kahle kokuphepha: Isithando sokushisa sikagesi sokudlulisa ukushisa komlilo asinawo amalangabi avulekile, sinciphisa izingozi zomlilo. Phakathi naleso sikhathi, isistimu ivame ukuhlonyiswa ngamadivaysi ahlukahlukene okuvikela ukuphepha, njengokuvikela ukushisa ngokweqile, ukuvikelwa kokuvuza, njll. Uma izinga lokushisa lamafutha okudlulisa ukushisa lidlula umkhawulo ophezulu obekiwe wokushisa okuphephile, idivayisi yokuvikela ukushisa ngokweqile izonqamula ngokuzenzakalelayo ukunikezwa kwamandla ukuvimbela amafutha okudlulisa ukushisa ekushiseni, ukubola, noma ngisho nokubamba umlilo; Idivayisi yokuvikela ukuvuza inganqamula ngokushesha isekethe uma kwenzeka kuvuza, iqinisekise ukuphepha kwabaqhubi.

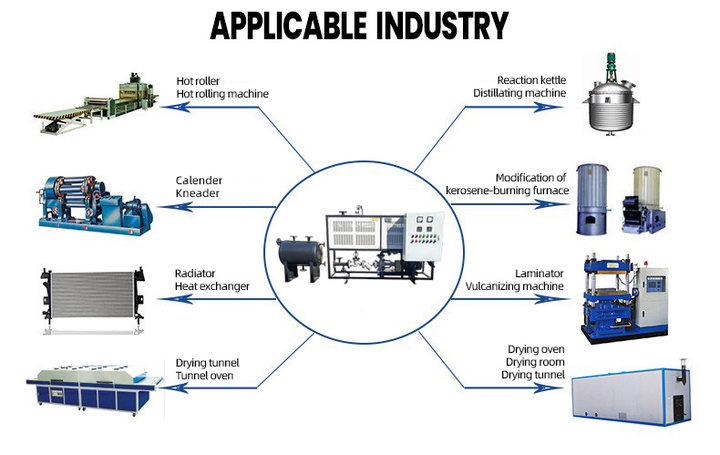

3. Isicelo:

Imboni yamakhemikhali: Ekuphenduleni kwamakhemikhali, njengokukhiqiza izinhlanganisela ze-organosilicon ezihlanzekile kakhulu, izinga lokushisa lokusabela liyadingeka ngokuqinile futhi ukungcola akukwazi ukuxutshwa phakathi nenqubo yokusabela. Isithando somlilo esishisayo sikagesi esishisayo singanikeza umthombo wokushisa ozinzile, futhi indlela yayo yokushisa ehlanzekile ayingenisi ukungcola okuvuthayo, iqinisekisa ukuhlanzeka komkhiqizo. Futhi izinga lokushisa lingalawulwa ngokusho kwesiteji sokusabela, njengokulawula izinga lokushisa phakathi kuka-150-200℃esigabeni sokuhlanganisa ama-organosilicon monomers nama-200-300℃esigabeni se-polymerization.

Imboni eyenza imithi: Ngokusabela kokuhlanganiswa kwezithako ezisebenzayo emithini, izinguquko ezincane zokushisa zingathinta ikhwalithi nokusebenza kwezidakamizwa. Isithando somlilo esishisayo sikagesi singahlangabezana nezidingo zokulawula izinga lokushisa ezinembile kakhulu zemikhumbi yokusabela kwemithi. Isibonelo, ekushiseni kwemikhumbi yokusabela esetshenziselwa ukukhiqizwa kwezidakamizwa ezilwa nomdlavuza, ukulawulwa kwezinga lokushisa kungaqinisekisa ukunemba kwesakhiwo samangqamuzana ezidakamizwa futhi kuthuthukise ukusebenza kwezidakamizwa. Ngesikhathi esifanayo, izici zemvelo zokushisa kagesi kanye nokushisa kwamafutha okushisa okushisayo nakho kuhambisana nezindinganiso eziqinile zemvelo embonini yezemithi.

Imboni yokudla: Ekuhlanganiseni nasekusetshenzisweni kwezithasiselo zokudla, njengokukhiqizwa kwama-emulsifiers, ama-thickeners, njll., kusetshenziswa ukushisa kweketela lokusabela. Indlela yokushisa ehlanzekile yesithando somlilo sikagesi esishisayo ingagwema izinto eziyingozi ezikhiqizwe ukushiswa kokungcolisa izinto zokusetshenziswa zokudla, ukuqinisekisa ukuphepha kokudla. Futhi izinga lokushisa lokushisa lingalawulwa, isibonelo, ekushiseni kweketela lokuphendula lokukhiqiza i-gelatin, ngokulawula izinga lokushisa ngaphakathi kwebanga elifanele (njenge-40-60℃), ikhwalithi nokusebenza kwe-gelatin kungaqinisekiswa.

Isikhathi sokuthumela: Dec-20-2024