Ipayipi le-industrial electric high pressure pipeline inline air heater

Isingeniso Somkhiqizo

I-heater inline air heater iyisisetshenziswa esisebenzisa amandla kagesi ukushisisa umoya ogeleza ngamapayipi noma amapayipi. Ifakwe ngokuqondile ekugelezeni komoya. Uma umoya ugeleza ngesivutheli epayipini/ipayipi, amandla adlula endaweni yokushisisa ukumelana efakwe ngaphakathi kwepayipi. Ngalesi sikhathi, umoya ogeleza phakathi kwe-elementi udonsa ukushisa ngokusebenzisa i-convection, futhi izinga lokushisa lomoya ophumayo lilawulwa futhi liqashwe ngesilinganiso sokushisa kwe-thermocouple nesilawuli (ngokusekelwe ku-PID, SSR).

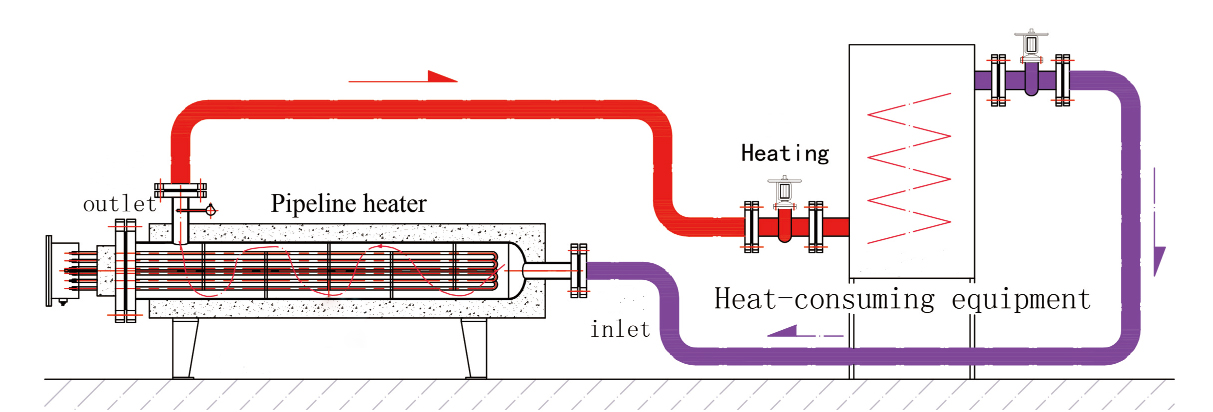

Isimiso sokusebenza

PI-ipeline heater kagesi iyithuluzi elisebenzisa amandla kagesi ukuze liwaguqule libe amandla ashisayo okufudumeza okudingayo. Ngesikhathi sokusebenza, uketshezi olunezinga lokushisa eliphansi lungena endaweni yalo ngaphansi kwengcindezi, lugeleze eziteshini ezithile zokushintshanisa ukushisa ngaphakathi komkhumbi wokushisisa kagesi, futhi lulandela indlela eklanywe ngokusekelwe ezimisweni ze-thermodynamics eziwuketshezi, zithwala amandla okushisa aphakeme okushisa akhiqizwa izinto zokushisisa zikagesi, ngaleyo ndlela andise izinga lokushisa lendawo eshisisayo I-outlet ye-heater kagesi ithola okuphakathi okudingekayo ngenqubo yokushisa ephezulu. Isistimu yokulawula yangaphakathi ye-heater kagesi ilawula ngokuzenzakalelayo amandla okukhishwa kwe-heater ngokusho kwesignali yenzwa yokushisa ekuphumeni, ukugcina izinga lokushisa elilinganayo le-medium at outlet; lapho into yokushisisa ishisa ngokweqile, idivayisi yokuvikela ngaphezu kwesici sokushisa inqamula ngokushesha amandla okushisa, ivimbele okokushisisa ekushiseni ngokweqile, okubangela i-coke, ukuwohloka, kanye ne-carbonization, kanye nezimo ezinzima, okubangela ukuthi isici sokushisisa sishise, sinwebe ngempumelelo impilo yesevisi ye-heater kagesi.

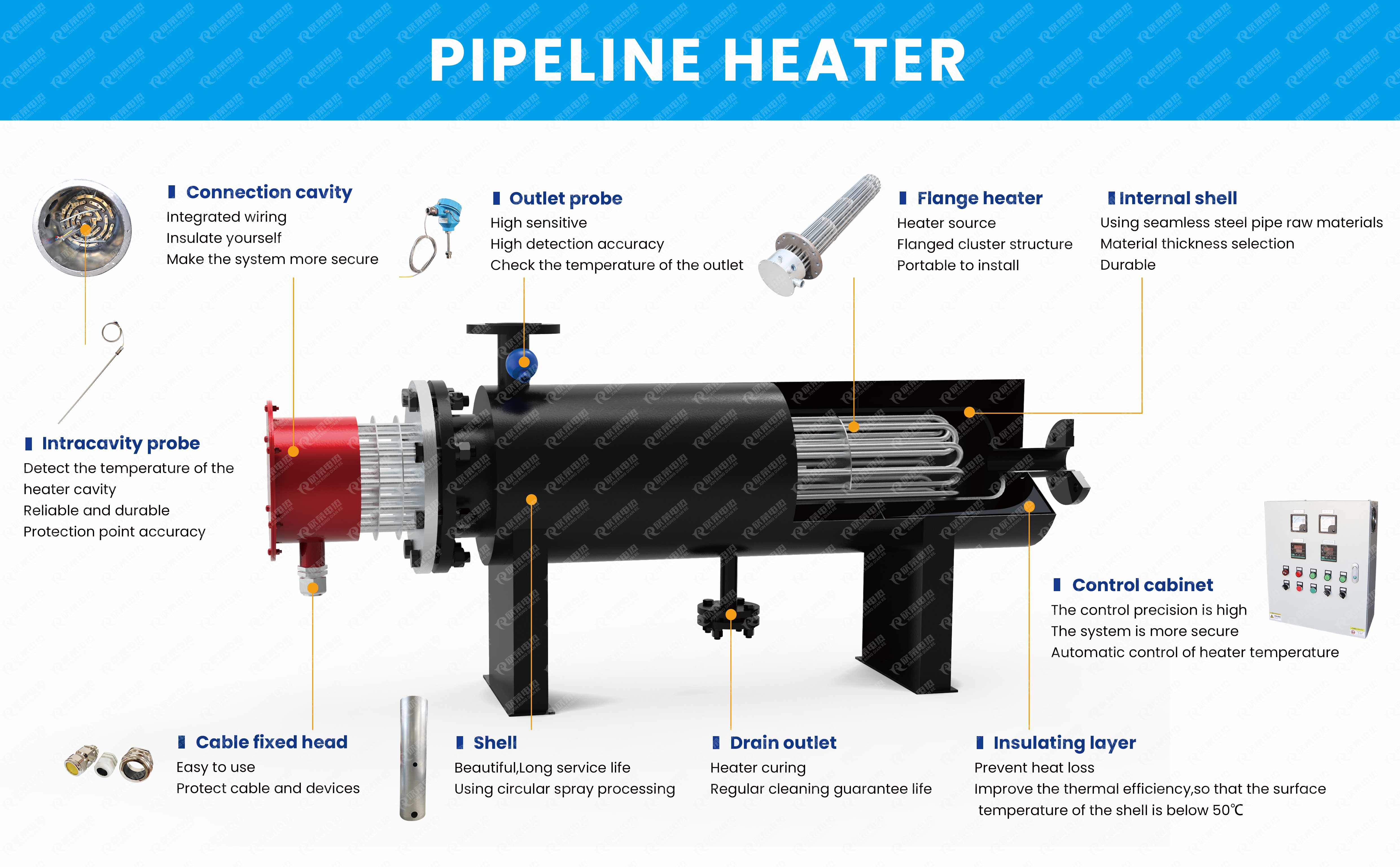

Imininingwane yomkhiqizo iyaboniswa

IaI-ir circulation pipeline heater yakhiwe izingxenye ezimbili: umzimba kanye nesistimu yokulawula.Isici sokushisisa ngogesi siphehla ukushisa: Isici sokushisa sikagesi ku-heater siyingxenye eyinhloko yokukhiqiza ukushisa. Lapho amandla kagesi edlula kulezi zakhi, akhiqiza ukushisa okukhulu.

Ukushisisa okuphoqiwe kwe-convection: Uma i-nitrogen noma enye into ephakathi idlula ku-heater, isiphephetha-moya sisetshenziselwa ukuphoqa ukuguquguquka, ukuze okuphakathi kugeleze futhi kudlule endaweni yokushisisa. Ngale ndlela, i-medium, njengesithwali sokushisa, ingakwazi ukudonsa ngokuphumelelayo ukushisa futhi idlulisele ohlelweni oludinga ukushiswa.

Ukulawula izinga lokushisa: I-heater ifakwe isistimu yokulawula ehlanganisa inzwa yokushisa nesilawuli se-PID. Lezi zingxenye zisebenza ndawonye ukuze zilungise ngokuzenzakalelayo amandla okukhishwa kwe-heater ngokuvumelana nezinga lokushisa eliphumayo, ukuqinisekisa ukuthi izinga lokushisa eliphakathi lizinzile ngenani elimisiwe.

Ukuvikela ukushisa ngokweqile: Ukuze uvimbele ukulimala kokushisa okweqile kusici sokushisa, i-heater nayo ifakwe izinto zokuvikela ukushisa ngokweqile. Ngokushesha lapho kutholakala ukushisa ngokweqile, idivayisi inqamula ngokushesha ukunikezwa kwamandla, ivikela isici sokushisa kanye nesistimu.

Isici somkhiqizo

- 1.Isebenza kahle futhi iyonga amandla: Amandla kagesi aguqulwa ngokuqondile abe amandla ashisayo ngokusebenza okuphakeme kokuguqulwa (ngokuvamile>95%). Idizayini enhle ye-insulation iphinde yehlise ukulahleka kokushisa.

I-2.Ukulawula ukushisa okunembile: Ukulawulwa kwe-PID kungafinyelela ukunemba kokulawula izinga lokushisa kwe-± 1 ° C, ukuhlangabezana nezidingo eziqinile zenqubo.

3.Impendulo esheshayo: Ukushisisa ngogesi kuqala ngokushesha futhi izinga lokushisa lokwenyuka nokuwa liyashesha kakhulu.

4.Ihlanzekile futhi ihambisana nemvelo: Akukho nqubo yokuvutha, akukho gesi yokukhipha umoya, intuthu noma amalangabi akhiqizwayo, futhi indawo yokusebenza ihlanzekile.

5.Kulula ukuzenzela: Kulula ukuhlanganisa ezinhlelweni ze-PLC/DCS zokuqapha okukude nokulawula okuzenzakalelayo.

6.Kulula ukufaka: ngokuvamile ixhunywe nge-flange futhi ixhunywe epayipiningqo.

7.Idizayini eguquguqukayo: Amandla, usayizi, kanye nesakhiwo (njengohlobo lokuvikela ukuqhuma) kungenziwa ngokwezifiso ngokuya ngesilinganiso sokugeleza kwegesi, izidingo zokukhuphuka kwezinga lokushisa, usayizi wamapayipi, ingcindezi, ukwakheka kwegesi, njll.

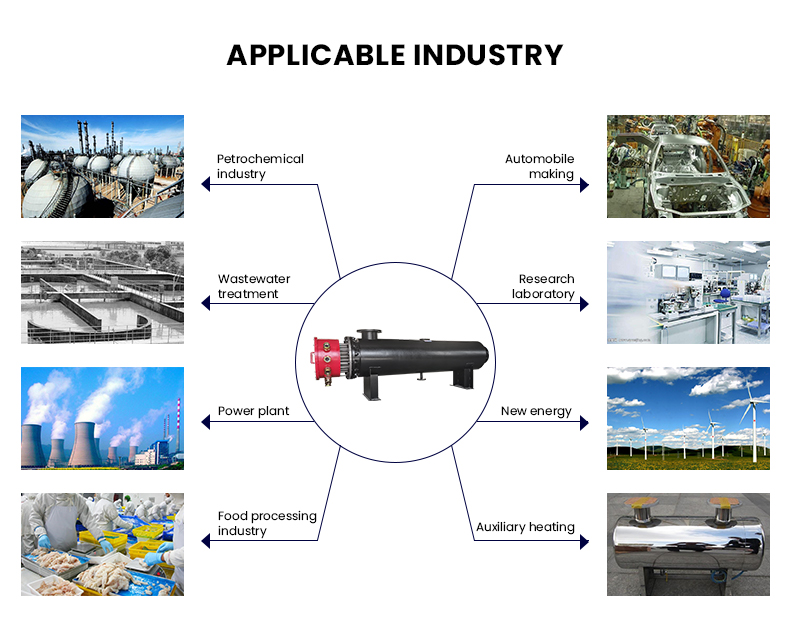

Isicelo somkhiqizo

Izifudumezi zomoya ezisemgqeni wepayipi zisetshenziswa kabanzi kwabaningi izimo zohlelo lokusebenza, njenge:

I-Chemical and Petrochemical: Amagesi enqubo yokushisa (njenge-nitrogen, i-hydrogen, i-argon, i-carbon dioxide, igesi eqhekekayo, igesi esabelayo), ukuvimbela ukufiphala kwegesi, ukushisa kwangaphambili ngaphambi kokukhishwa kwegesi ne-denitrification, njll.

Uwoyela negesi yemvelo: ukushisisa igesi yemvelo (i-antifreeze, i-depressurization kanye ne-anti icing), igesi ehambisanayo, i-flare gas, ukushisisa amapayipi ngemva kokufakwa kwegesi ye-petroleum gasification (LPG), ukuphelelwa amandla kwamanzi kwegesi yemvelo/ukufudumeza kwangaphambi kwemitha, njll.

Ugesi: Ukushisa kwe-boiler air (umoya oyinhloko, umoya wesibili), ukushisisa kabusha kwegesi ye-flue yesistimu ye-desulfurization, njll.

Ukuvikelwa kwemvelo: Ukushisa ngaphambili kwegesi ephumayo ekulashweni kwegesi yemfucuza ye-VOC (i-catalytic combustion, i-RTO/RCO).

Ilabhorethri: Ukulawulwa okunembile kwezinga lokushisa legesi lokuhlola.

Futhi njll....

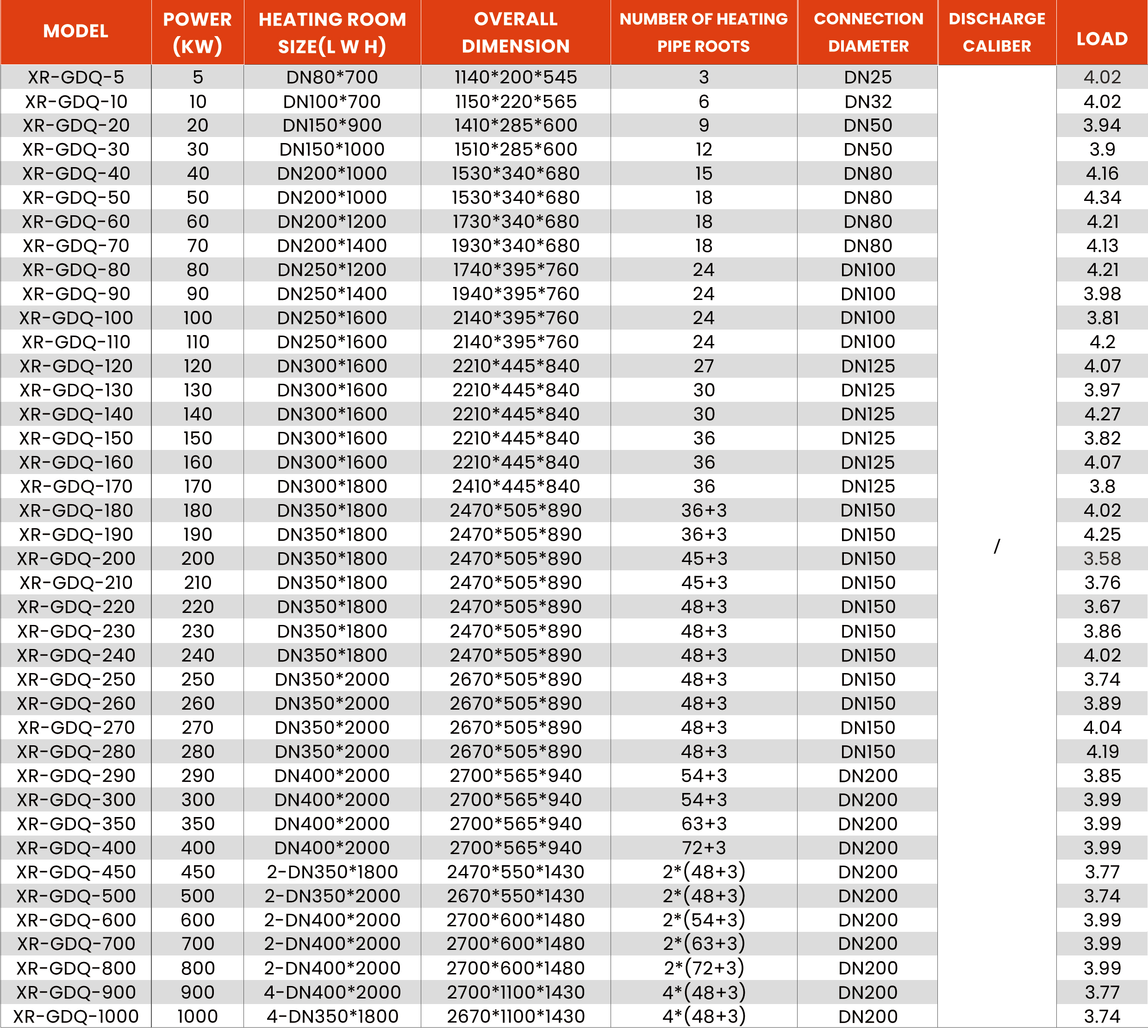

Imininingwane Yobuchwepheshe

Icala lokusebenzisa ikhasimende

Umsebenzi omuhle, ukuqinisekiswa kwekhwalithi

Sithembekile, singochwepheshe futhi siyaphikelela, ukukulethela imikhiqizo emihle kakhulu kanye nenkonzo yekhwalithi.

Sicela uzizwe ukhululekile ukusikhetha, masifakazele amandla ekhwalithi ndawonye.

Isitifiketi kanye neziqu

Ukupakishwa komkhiqizo kanye nokuhamba

Ukupakishwa kwezisetshenziswa

1) Ukupakisha emacaleni okhuni angenisiwe

2) Ithreyi ingenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende

Ukuthuthwa kwempahla

1) Express (isampula oda) noma ulwandle (oda ngobuningi)

2) Izinsizakalo zokuthumela emhlabeni wonke