I-heater kagesi eshisayo esebenza kahle kakhulu yokushisisa i-reactor

Imininingwane Yomkhiqizo

I-heater kawoyela eshisayo iwuhlobo lwemishini yokushisisa yohlobo olusha olunokuguqulwa kwamandla okushisa. Ithatha ugesi njengamandla, iwuguqule ibe amandla okushisa ngokusebenzisa izitho zikagesi, ithatha isithwali sezinto eziphilayo (uwoyela oshisayo oshisayo) njengento ephakathi, futhi iyaqhubeka nokushisa ngokujikeleza okuphoqelekile kokushisa Amafutha ashisayo aqhutshwa iphampu kawoyela enezinga lokushisa eliphezulu, ukuze kuhlangatshezwane nezidingo zokushisa zabasebenzisi. Ngaphezu kwalokho, ingase futhi yanelise izimfuneko zezinga lokushisa elimisiwe kanye nokunemba kokulawula izinga lokushisa. Senzelwa amandla asuka ku-5 kuye ku-2,400 kw kanye namazinga okushisa afinyelela ku-+320 °C.

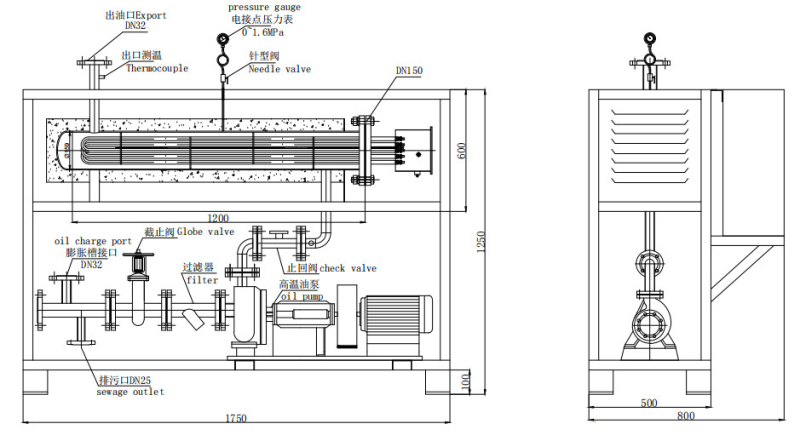

Umdwebo osebenzayo (we-laminator)

Izici

(1) Isebenza ngengcindezi ephansi futhi ithole izinga lokushisa eliphezulu lokusebenza.

(2) Ingathola ukushisa okuzinzile kanye nezinga lokushisa elinembile.

(3) I-Thermal Oil Heater inamadivayisi aphelele okulawula ukusebenza kanye nokuqapha ukuphepha.

(4) Isithando somlilo sikawoyela esishisayo sisiza ukonga ugesi, uwoyela namanzi, futhi singabuyisa utshalomali ezinyangeni ezi-3 kuya kweziyisi-6.

Izinyathelo zokuzivikela

1. Ngesikhathi sokusebenza kwesithando somlilo samafutha okushisa, lapho kusetshenziswa amafutha okushisa ukushisa, ipompo yamafutha ejikelezayo kufanele iqale kuqala. Ngemuva kwesigamu sehora lokusebenza, izinga lokushisa kufanele liphakanyiswe kancane ngesikhathi sokushiswa.

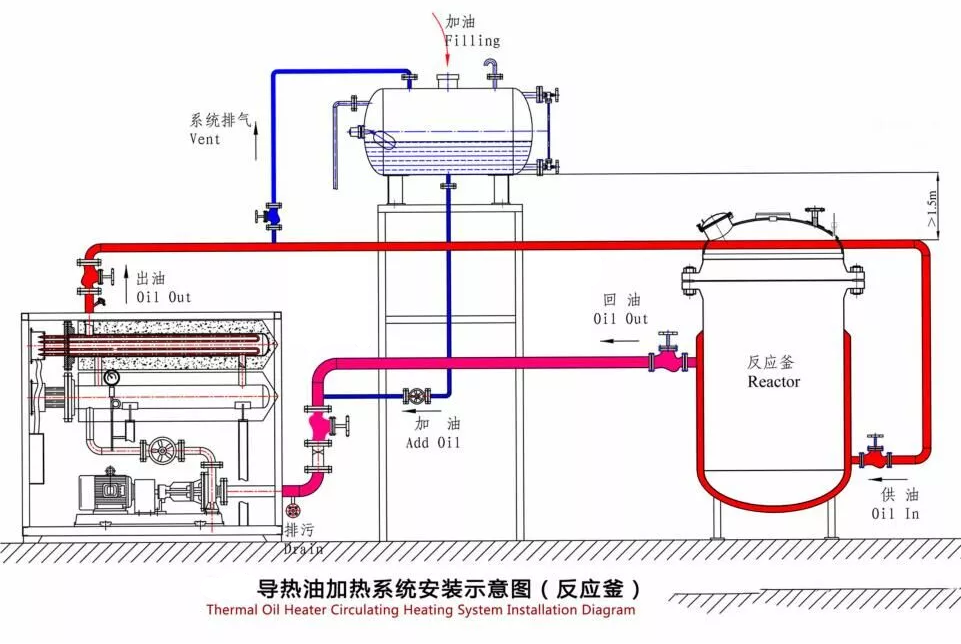

2. Ngalolu hlobo lwe-boiler olunamafutha okudlulisa ukushisa njengesithwali sokushisa, uhlelo lwayo kufanele lufakwe ithangi lokunweba, ithangi lokugcina uwoyela, izingxenye zokuphepha kanye nemishini yokulawula.

3. Ngesikhathi sokusebenzisa i-boiler, kufanele ihlolwe ngokucophelela. Qaphela ukuvuza kwamanzi, i-asidi, i-alkali nezinto zamaphuzu aphansi abilayo ohlelweni lwesithando somlilo esibamba ukushisa. Uhlelo kufanele lufakwe imishini yokuhlunga ukuze kugwenywe ukungena kwezinye imfucumfucu ukuze kuqinisekiswe ukuhlanzeka kwamafutha.

4. Ngemuva kokusebenzisa isithando somlilo samafutha isigamu sonyaka, uma kutholakala ukuthi umphumela wokudlulisa ukushisa umpofu, noma ezinye izimo ezingavamile zenzeka, ukuhlaziywa kwamafutha kufanele kwenziwe.

5. Ukuze kuqinisekiswe umphumela ovamile wokushisa ukushisa kwamafutha okudlulisa ukushisa kanye nempilo yesevisi ye-boiler, akuvunyelwe ukusebenzisa i-boiler ngaphansi kwesenzo sokushisa okungaphezulu.