Isifudumezi Sepayipi Esingaqhumi

Imininingwane Yomkhiqizo

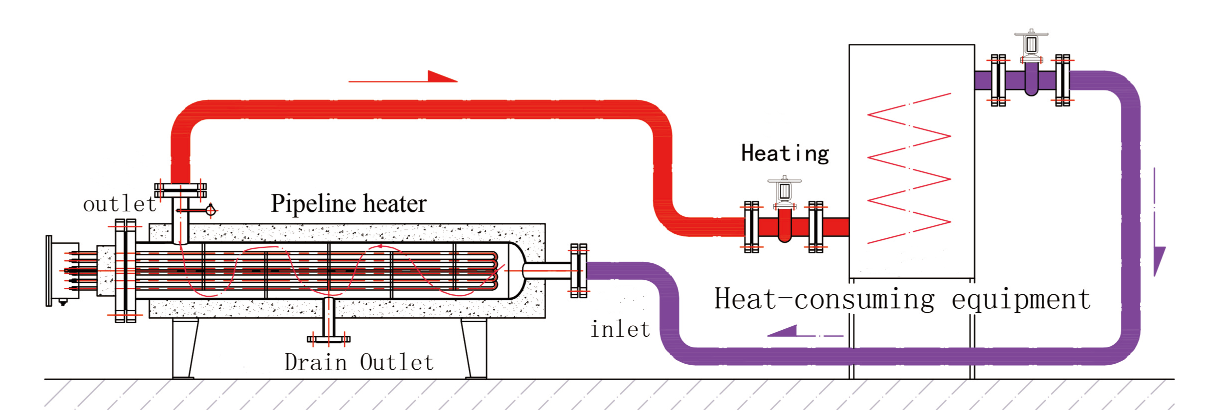

I-heater yepayipi iwuhlobo lwemishini yokonga amandla eshisa kuqala into. I-heater yepayipi ingahlukaniswa ibe izindlela ezimbili: enye iwukusebenzisa uhlobo lwe-flange lwe-tubular yokushisa kagesi kagesi ngaphakathi kwe-heater yepayipi ukushisisa uwoyela we-conduction kubhantshi le-reactor ku-heater yepayipi, futhi udlulise amandla okushisa ku-heater yepayipi kumakhemikhali aluhlaza ku-reactor ngaphakathi kwe-heater yepayipi Enye indlela ukufaka i-tubular heater kagesi heater ku-heater kagesi ku-heater kagesi ngqo ku-heater kagesi ukusabalalisa amashubhu okushisa kagesi eduze kodonga lwe-heater tubular. Le modi ibizwa ngokuthi uhlobo lokushisa lwangaphakathi lwe-heater yepayipi. Uhlobo lokushisa lwangaphakathi lwe-heater yamapayipi lunezinzuzo zokukhuphuka kwezinga lokushisa okusheshayo nokusebenza kahle okuphezulu.

Lapho i-heater yepayipi ngogesi izovela umphumela wokuzifudumeza, okubangela ukuthi isincibilikisi noma ama-molecule wamanzi aku-heater yamapayipi ahwamuke. Isizukulwane sokushisa se-heater siyiyunifomu, ngaleyo ndlela sigwema ukuguquguquka nokuguqulwa kwekhwalithi ye-heater yepayipi ngenxa yezinga lokukhuliswa okushisayo, ukuze ukubukeka kwezinto ezibonakalayo, izakhiwo zomzimba nezomshini, ukusheshisa nombala we-heater pipe zigcinwe ziqinile.

Isicelo

Izifudumezi zamapayipi zisetshenziswa kakhulu kwezezimoto, zendwangu, ukuphrinta nokudaya, odayi, iphepha, ibhayisikili, isiqandisi, umshini wokuwasha, i-chemical fiber, i-ceramics, isifutho se-electrostatic, ukudla, ukudla, imithi, amakhemikhali, ugwayi nezinye izimboni ukufeza ukomiswa okusheshayo kwamapayipi amapayipi. inhloso. Isifudumezi sepayipi sinomphumela omuhle wemisebe, isifudumezi sepayipi sinokonga amandla okusobala, futhi izinzuzo zokusebenzisa nokugcinwa zisesimweni esikahle. Ukushisisa kwe-heater yamapayipi nakho kulungele ikakhulukazi igumbi elikhulu lokomisa, ihhavini nomhubhe wokomisa amanzi wemishini yesikhumba.

Inzuzo

*Ukushintsha umsebenzi wamandla okushisa futhi kungenziwa ngezifiso;

*Izinga lokushisa lingalungiswa ngokukhululekile ku-RT- 800 °C;

*Ukukhipha okuzenzakalelayo lapho uqala;

*Ukubambezeleka kokupholisa lapho ucisha, futhi kungenziwa ngezifiso;

*Ukulawula izinga lokushisa kwamaphoyinti amaningi futhi kungenziwa ngezifiso;

*Ukutholwa kokucindezeleka kanye ne-alamu;

*Ukutholwa kwezinga lokushisa ne-alamu;

*Ihitha yethu inobufakazi bokuqhuma, ingaba yi-OEM.