Isifudumezi sepayipi esingaqhumi

Isimiso sokusebenza

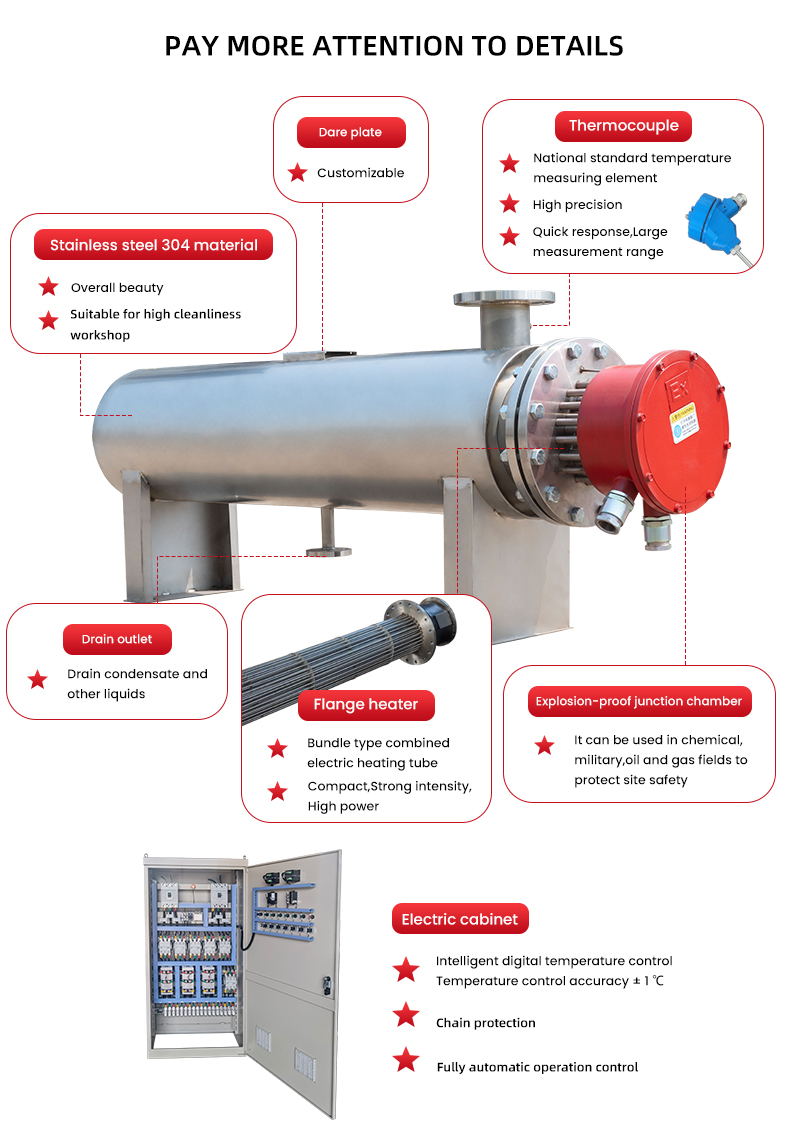

Isimiso sokushisisa amapayipi angaqhumi sisekelwe kakhulu ohlelweni lokuguqula amandla kagesi abe ukushisa. Ngokuqondile, i-heater kagesi iqukethe isici sokushisa kagesi, ngokuvamile intambo yokumelana nokushisa okuphezulu, eshisa lapho i-current idlula, futhi ukushisa okubangelwayo kudluliselwa ku-fluid medium, ngaleyo ndlela kushise uketshezi.

I-heater kagesi iphinde ifakwe uhlelo lokulawula, okuhlanganisa izinzwa zokushisa, izilawuli zokushisa zedijithali kanye ne-solid-state relays, okuhlangene kwakha isilinganiso, i-loop yokulawula kanye nokulawula. Inzwa yezinga lokushisa ithola izinga lokushisa lokukhipha uketshezi futhi idlulisele isignali kusilawuli sezinga lokushisa ledijithali, esilungisa okukhiphayo kwe-solid state relay ngokwenani lokushisa elimisiwe, bese lilawula amandla we-heater kagesi ukuze kugcinwe ukuzinza kwezinga lokushisa kwendawo ewuketshezi.

Ngaphezu kwalokho, i-heater kagesi ingase futhi ifakwe idivayisi yokuvikela ukushisa ngokweqile ukuvimbela isici sokushisa ekushiseni ngokweqile, ukugwema ukuwohloka okuphakathi nendawo noma ukulimala kwemishini ngenxa yokushisa okuphezulu, ngaleyo ndlela kuthuthukiswe ukuphepha nokuphila kwemishini.

Imininingwane yomkhiqizo iyaboniswa

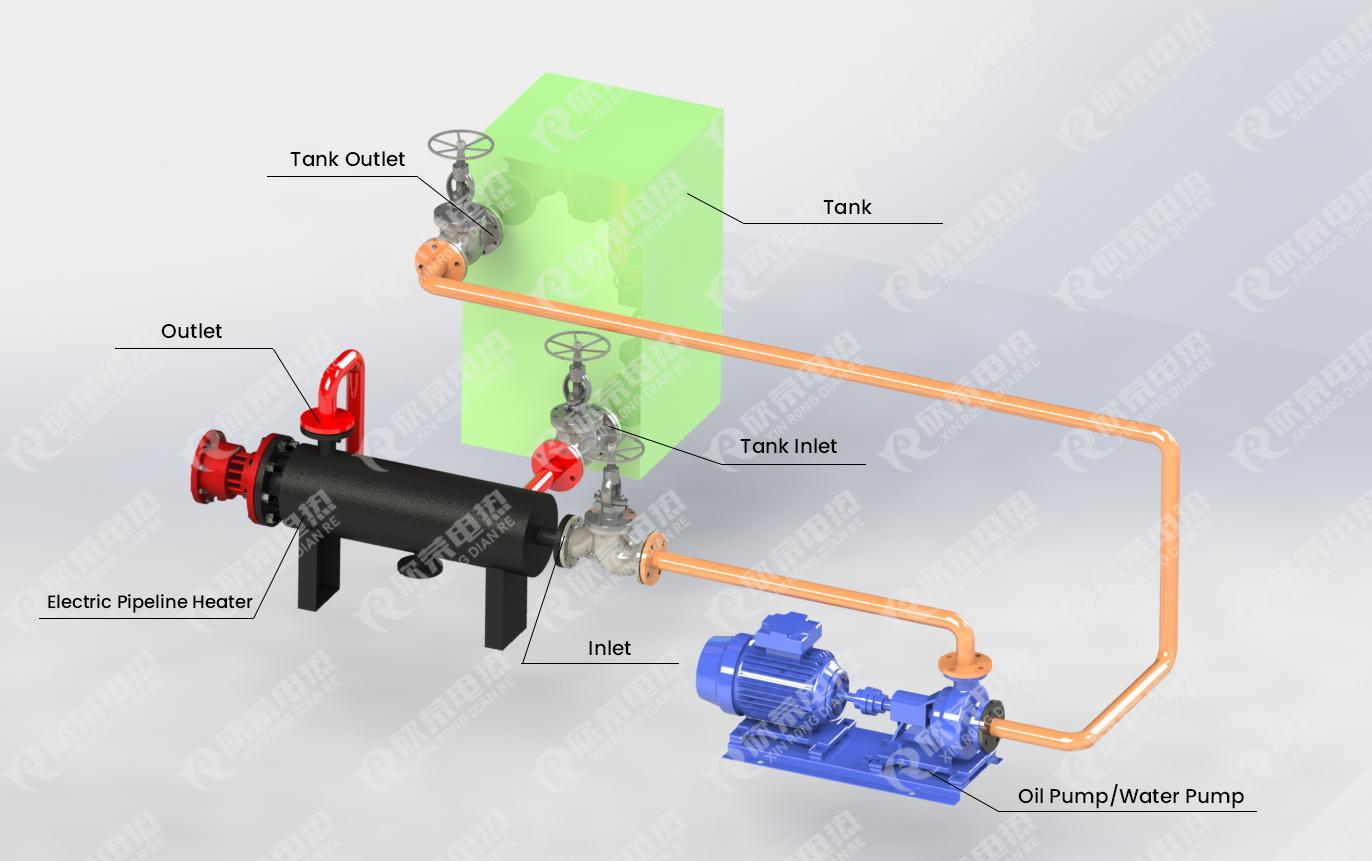

Uhlolojikelele lwesicelo sesimo sokusebenza

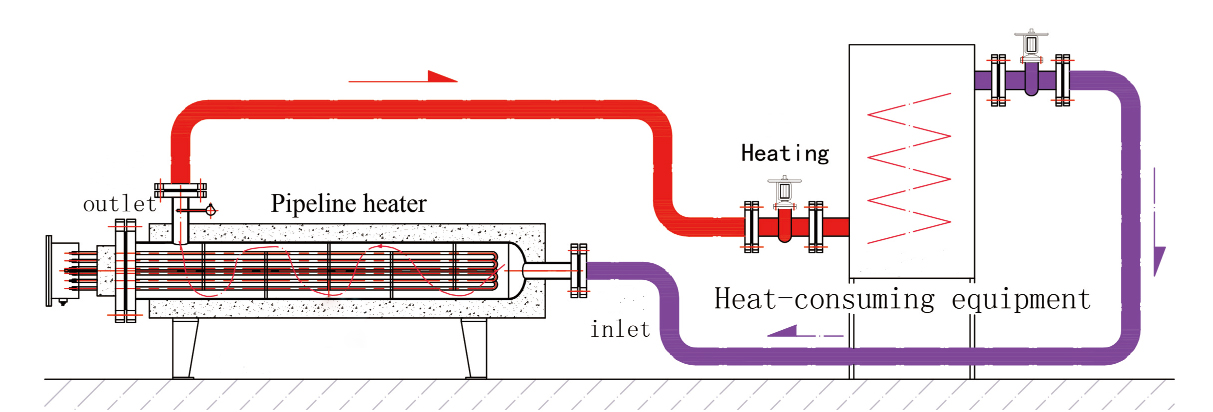

Umgomo wokusebenza kwesifudumezi sikagesi esingaqhumi ukuguqula amandla kagesi abe amandla okushisa ukuze kushisise uketshezi.

Enkambweni yokushisa, i-fluid ephansi yezinga lokushisa eliphansi kuqala idlula ipayipi bese ingena echwebeni lokufaka le-heater kagesi ngaphansi kwesenzo sokucindezela. Khona-ke, igeleza eduze komgijimi othize wokushintshanisa ukushisa ngaphakathi komkhumbi wokushisisa kagesi, oklanywe ngokwezimiso ze-thermodynamics ewuketshezi ukuze udlulise ukushisa kahle. Kule nqubo, ukushisa okuphezulu okushisa okukhiqizwa yisici sokushisa kagesi kuthathwa uketshezi, okuholela ekwandeni kwezinga lokushisa le-fluid medium.

Isistimu yokulawula ngaphakathi kwe-heater kagesi ilungisa ngokuzenzakalelayo amandla okukhiphayo ngokuya ngesignali yenzwa yezinga lokushisa endaweni yokuphuma. Inhloso yalokhu ukugcina izinga lokushisa le-outlet medium uniform. Ukwengeza, uma izinga lokushisa lesici sokushisa liphezulu kakhulu, idivayisi yokuvikela ukushisa okweqile okuzimele izonqamula ngokushesha ukunikezwa kwamandla okushisa ukuvimbela okuphakathi kusuka ekushiseni okweqile okubangela i-coking, ukuwohloka noma i-carbonization, ngaleyo ndlela ikhulise ngempumelelo impilo yesevisi ye-heater kagesi.

Izishisi zikagesi ezingaqhumi zifaneleka ikakhulukazi ezimweni lapho kungase kube khona indawo yegesi eqhumayo, njengemboni yamakhemikhali. Zenzelwe ukuthi zikwazi ukuvimbela ukuqhuma ukuze zivikele izinhlansi zikagesi noma ukushisa ngokweqile ekubangeleni izingozi. Lawa madivaysi ngokuvamile afakwa ezindlini ezingashi noma ezinye izindlela zokuvikela ukuqhuma ukuze kuqinisekiswe ukuthi awekho ama-arcing noma izinhlansi ezingabangela ukuqhuma ezikhiqizwa ngaphansi kokusebenza okuvamile noma izimo ezivunyelwe zokugcwala ngokweqile.

Isicelo somkhiqizo

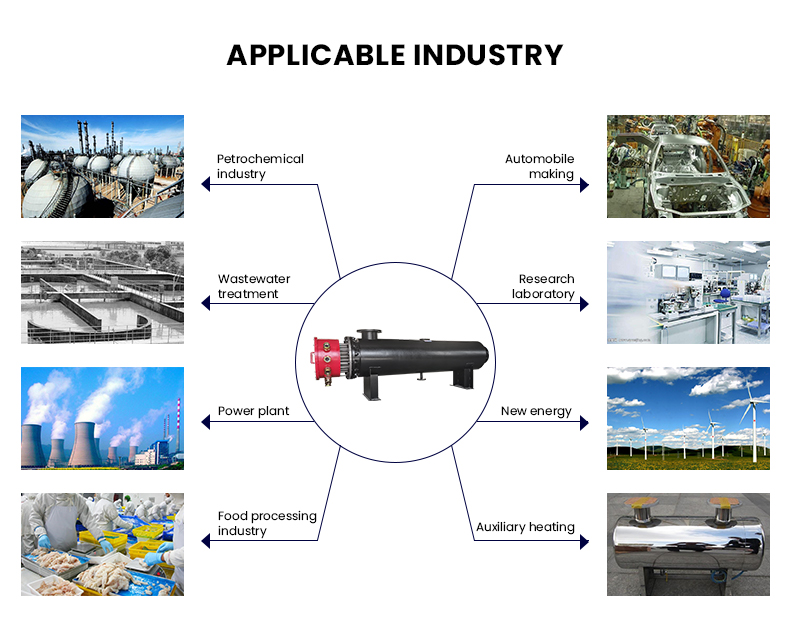

I-heater yamapayipi isetshenziswa kabanzi ku-aerospace, embonini yezikhali, embonini yamakhemikhali nasemakolishi nasemanyuvesi kanye nezinye ilabhorethri yocwaningo nokukhiqiza eminingi yesayensi. Ifaneleka ngokukhethekile ukulawulwa kwezinga lokushisa okuzenzakalelayo kanye nokugeleza okukhulu kokushisa okuphezulu okuhlanganisiwe uhlelo kanye nokuhlolwa kwesesekeli, indawo yokushisa yomkhiqizo ayi-conductive, ayishisi, ayiqhumi, ayikho ukugqwala kwamakhemikhali, akukho ukungcola, iphephile futhi inokwethenjelwa, futhi indawo yokushisa iyashesha (siyalawuleka).

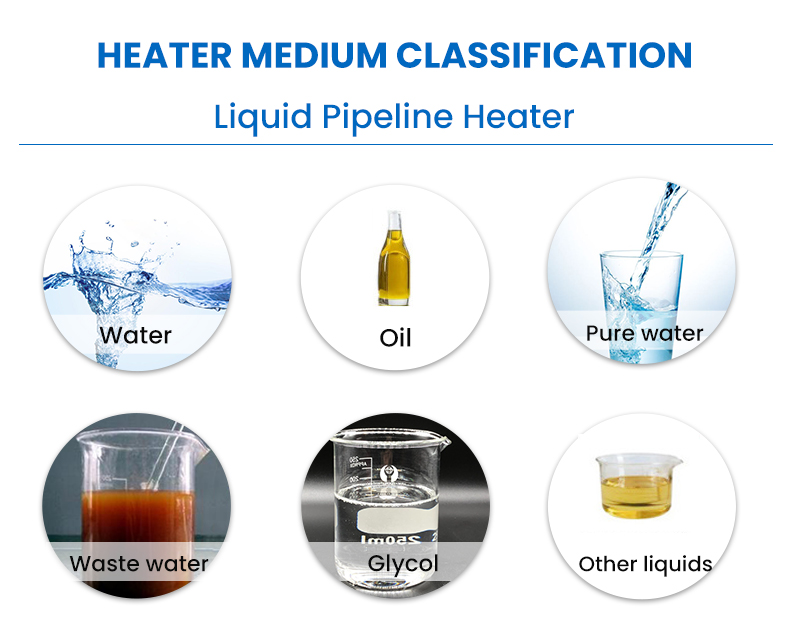

Ukuhlukaniswa kwe-heater medium

Icala lokusebenzisa ikhasimende

Umsebenzi omuhle, ukuqinisekiswa kwekhwalithi

Sithembekile, singochwepheshe futhi siyaphikelela, ukukulethela imikhiqizo emihle kakhulu kanye nenkonzo yekhwalithi.

Sicela uzizwe ukhululekile ukusikhetha, masifakazele amandla ekhwalithi ndawonye.

Isitifiketi kanye neziqu

Ukupakishwa komkhiqizo kanye nokuhamba

Ukupakishwa kwezisetshenziswa

1) Ukupakisha emacaleni okhuni angenisiwe

2) Ithreyi ingenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende

Ukuthuthwa kwempahla

1) Express (isampula oda) noma ulwandle (oda ngobuningi)

2) Izinsizakalo zokuthumela emhlabeni wonke