I-heater yamanzi kagesi engu-50KW

Isingeniso Somkhiqizo

Isifudumezi esisemgqeni wamanzi sakhiwe ngehitha yokucwiliswa embozwe yigumbi lomkhumbi wensimbi elilwa nokugqwala. Le casing isetshenziswa kakhulu ukuvikela ukulahleka kokushisa ohlelweni lokujikeleza. Ukulahlekelwa ukushisa akusebenzi nje kuphela ngokusetshenziswa kwamandla kodwa kuzodala nezindleko zokusebenza ezingadingekile. Iyunithi yephampu isetshenziselwa ukuthutha uketshezi olungenayo luluyise ohlelweni lokujikeleza. Uketshezi lube selusakazwa futhi lushiswe kabusha kumjikelezo weluphu evaliwe eduze kwe-heater yokucwiliswa ngokuqhubekayo kuze kufike izinga lokushisa elifunekayo. Isisetshenziswa sokushisisa sizobe sesigeleza siphuma embotsheni ye-outlet ngesilinganiso esinqunyiwe sokugeleza esinqunywa indlela yokulawula izinga lokushisa. I-heater yamapayipi imvamisa isetshenziswa ekushisiseni okumaphakathi nedolobha, elabhorethri, imboni yamakhemikhali kanye nemboni yendwangu.

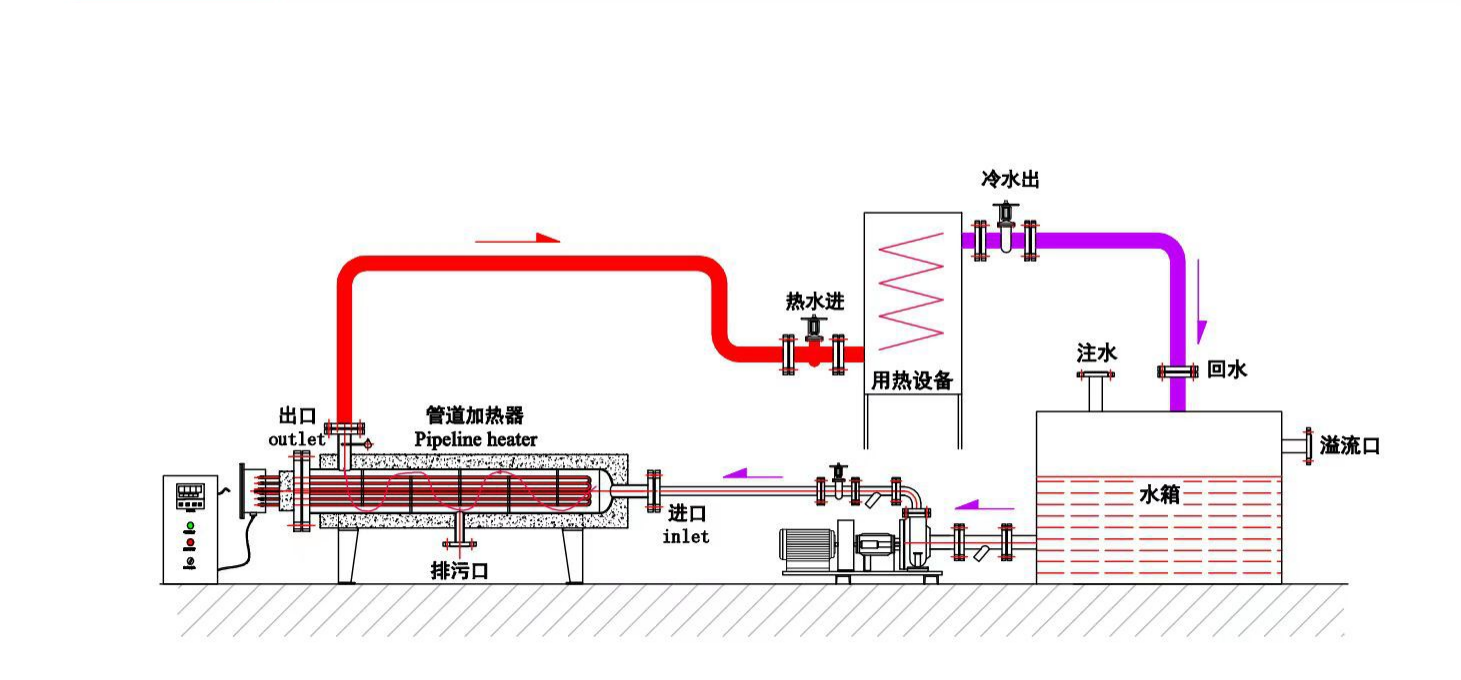

Umdwebo osebenzayo

Umgomo wokusebenza kwe-heater yamapayipi uthi: umoya obandayo (noma uketshezi olubandayo) ungena epayipini usuka endaweni yokungena, isilinda sangaphakathi se-heater sithintana ngokugcwele nento yokushisa kagesi ngaphansi kwesenzo se-deflector, futhi ngemva kokufinyelela izinga lokushisa elishiwo ngaphansi kokuqashwa kwesistimu yokulinganisa izinga lokushisa, ligeleza lisuka lapho liphuma liye ohlelweni olucacisiwe lwamapayipi.

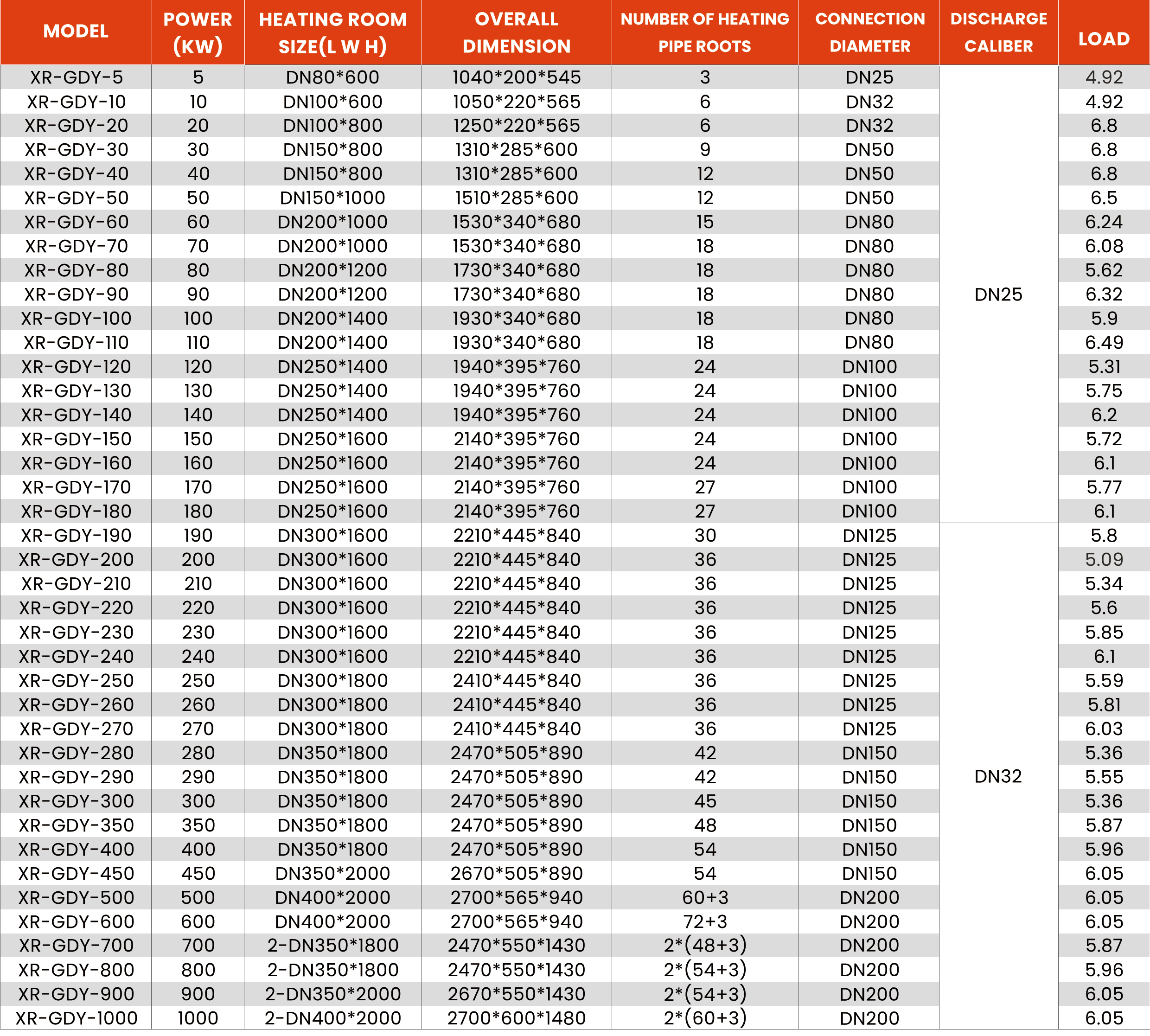

Imininingwane Yomkhiqizo

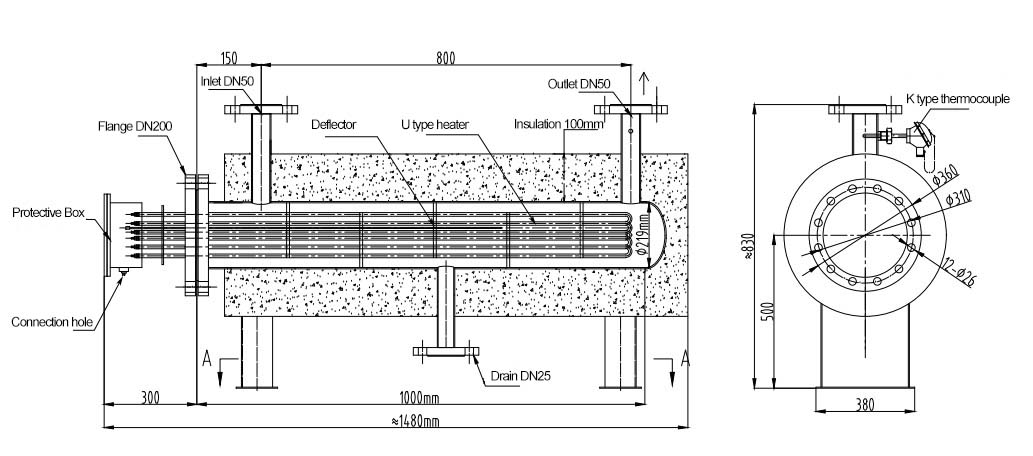

Ukwakheka Komkhiqizo

I-heater yepayipi yakhiwe ngokuyinhloko into yokushisa yokucwiliswa kagesi emise okuka-U, isilinda sangaphakathi, ungqimba olufakwa ngaphakathi, igobolondo elingaphandle, imbobo yezintambo, kanye nesistimu yokulawula kagesi.

Inzuzo

* I-Flange-form core yokushisa;

* Isakhiwo sithuthukisiwe, siphephile futhi siqinisekisiwe;

* Okufanayo, ukufudumeza, ukusebenza kahle kokushisa kuze kufike ku-95%

* Amandla amahle emishini;

* Kulula ukufaka nokuqaqa

* Ukonga amandla, izindleko eziphansi zokusebenza

* Ukulawula izinga lokushisa kwamaphuzu amaningi kungenziwa ngezifiso

* Izinga lokushisa eliphumayo liyalawuleka

Isicelo

Amapayipi okushisa asetshenziswa kakhulu ezimotweni, ezindwangu, ekunyatheliseni nasekudayeni, odayi, ekwenzeni iphepha, amabhayisikili, iziqandisi, imishini yokuwasha, imicu yamakhemikhali, i-ceramics, isifutho se-electrostatic, okusanhlamvu, ukudla, imithi, amakhemikhali, ugwayi nezinye izimboni ukuze kuzuzwe inhloso yokomisa amapayipi ngokushesha okukhulu. Izifudumezi zamapayipi ziklanyelwe futhi zenzelwe ukuguquguquka futhi ziyakwazi ukuhlangabezana nezinhlelo eziningi zokusebenza nezidingo zesayithi.

Umhlahlandlela Wokuthenga

Imibuzo ebalulekile ngaphambi koku-oda i-heater yamapayipi yilena: