isifudumezi somoya esicindezelwe

Isimiso sokusebenza

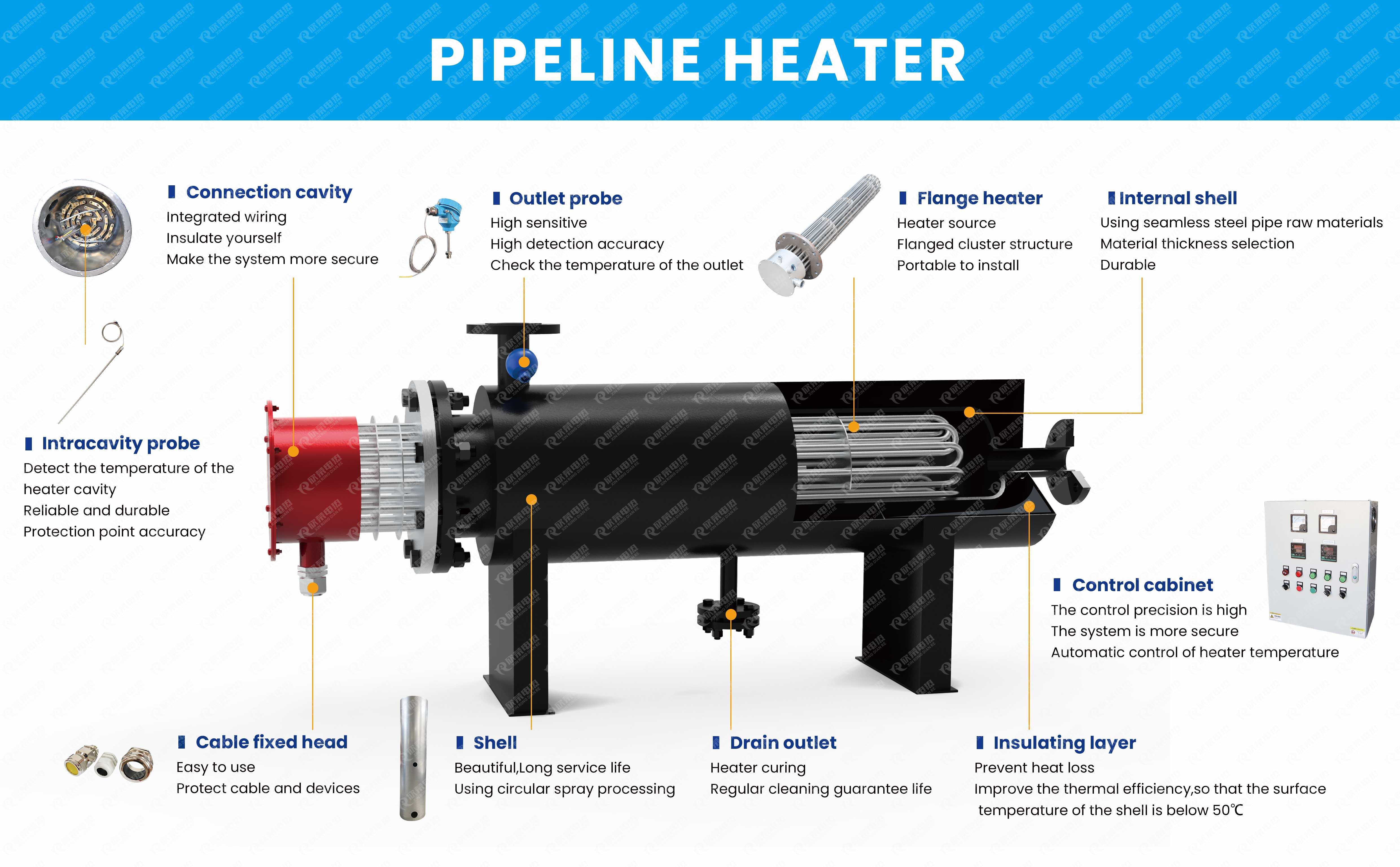

I-heater yomoya ecindezelwe yakhiwe izingxenye ezimbili: umzimba kanye nesistimu yokulawula.Isici sokushisa sikagesi sikhiqiza ukushisa: Isici sokushisa sikagesi ku-heater siyingxenye eyinhloko yokukhiqiza ukushisa. Lapho amandla kagesi edlula kulezi zakhi, akhiqiza ukushisa okukhulu.

Ukushisisa okuphoqiwe kwe-convection: Uma i-nitrogen noma enye into ephakathi idlula ku-heater, iphampu isetshenziselwa ukuphoqelela i-convection, ukuze okuphakathi kugeleze futhi kudlule endaweni yokushisisa. Ngale ndlela, i-medium, njengesithwali sokushisa, ingakwazi ukudonsa ngokuphumelelayo ukushisa futhi idlulisele ohlelweni oludinga ukushiswa.

Ukulawula izinga lokushisa: I-heater ifakwe isistimu yokulawula ehlanganisa inzwa yokushisa nesilawuli se-PID. Lezi zingxenye zisebenza ndawonye ukuze zilungise ngokuzenzakalelayo amandla okukhishwa kwe-heater ngokuvumelana nezinga lokushisa eliphumayo, ukuqinisekisa ukuthi izinga lokushisa eliphakathi lizinzile ngenani elimisiwe.

Ukuvikela ukushisa ngokweqile: Ukuze uvimbele ukulimala kokushisa okweqile kusici sokushisa, i-heater nayo ifakwe izinto zokuvikela ukushisa ngokweqile. Ngokushesha lapho kutholakala ukushisa ngokweqile, idivayisi inqamula ngokushesha ukunikezwa kwamandla, ivikela isici sokushisa kanye nesistimu.

Imininingwane yomkhiqizo iyaboniswa

Inzuzo yomkhiqizo

I-1, i-medium ingashiswa ekushiseni okuphezulu kakhulu, kuze kufike ku-850 ° C, izinga lokushisa legobolondo lingaba ngu-50 ° C kuphela;

2, ukusebenza kahle okuphezulu: kufika ku-0.9 noma ngaphezulu;

3, izinga lokushisa nokupholisa liyashesha, lifika ku-10℃/S, inqubo yokulungisa iyashesha futhi izinzile. Ngeke kube khona ukuhola kwezinga lokushisa kanye ne-lag phenomenon ye-medium elawulwayo, okuzobangela ukukhukhuleka kokushisa kokulawula, okulungele ukulawula okuzenzakalelayo;

I-4, izakhiwo ezinhle zemishini: ngoba umzimba wayo wokushisa uyisisetshenziswa esikhethekile se-alloy, ngakho-ke ngaphansi komthelela wokugeleza komoya ocindezelayo, kungcono kunanoma yiziphi izakhiwo zomshini wokushisa womzimba namandla, okudinga isikhathi eside esiqhubekayo sokushisa komoya kanye nokuhlolwa kwezesekeli kunenzuzo enkulu;

5. Uma ingaphuli inqubo yokusebenzisa, impilo ingaba yinde amashumi eminyaka ambalwa, ehlala isikhathi eside;

6, umoya ohlanzekile, usayizi omncane;

I-7, i-heater yepayipi ingaklanywa ngokuya ngezidingo zabasebenzisi, izinhlobo eziningi zama-heater kagesi omoya.

Uhlolojikelele lwesicelo sesimo sokusebenza

Lapho umoya ucindezelwa, ibanga eliphakathi kwama-athomu omoya liba lincane, okuholela ekwandeni kwamandla e-kinetic aphakathi kwama-molecule, akhiqiza ukushisa. Lokhu kushisa kubizwa ngokuthi ukushisa kokucindezela. Umoya ocindezelwe uzokhiqiza izinga lokushisa elithile ngesikhathi sokukhiqiza, kodwa leli zinga lokushisa lingase lingafinyeleli izinga lokushisa elilinganiselwe elidingwa abasebenzisi.

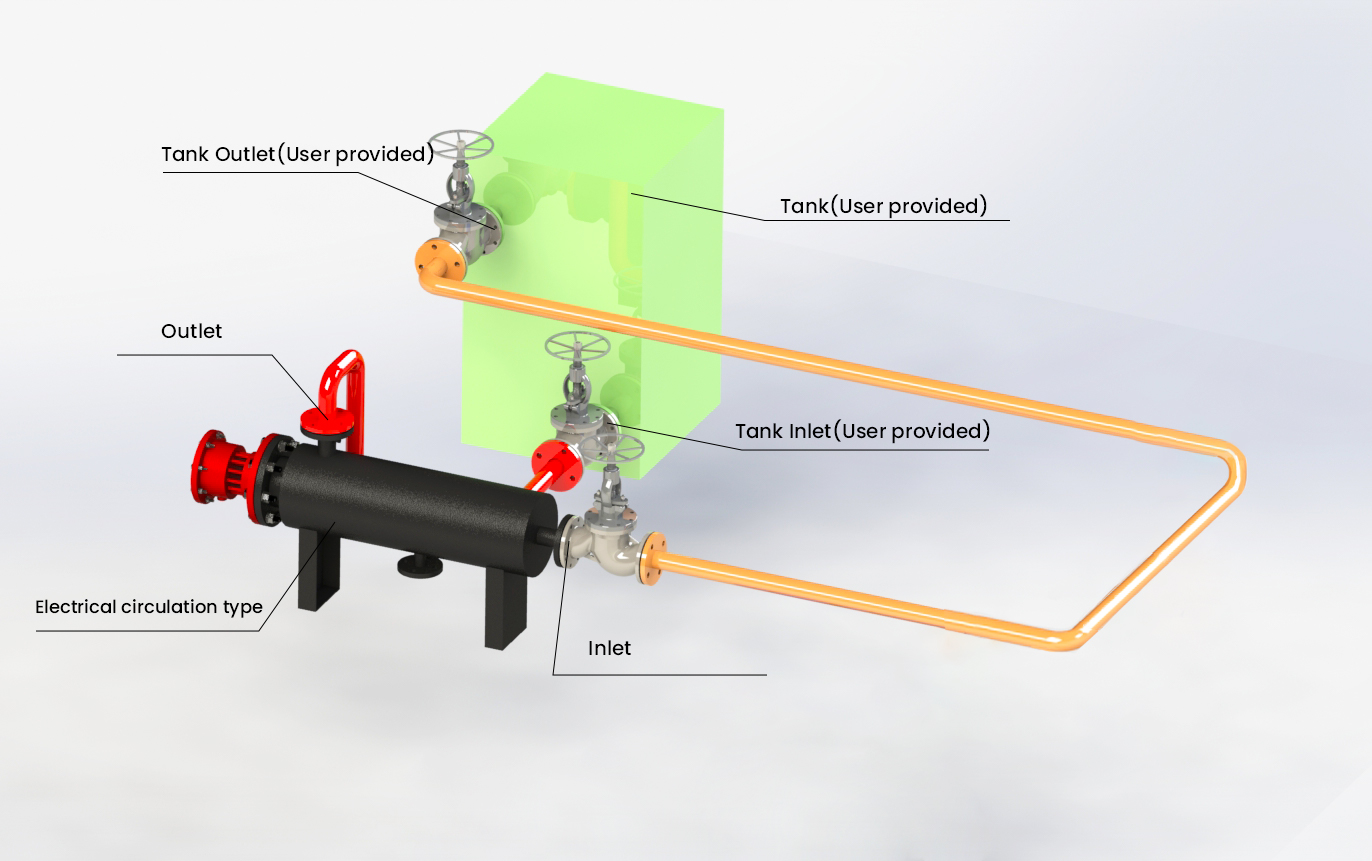

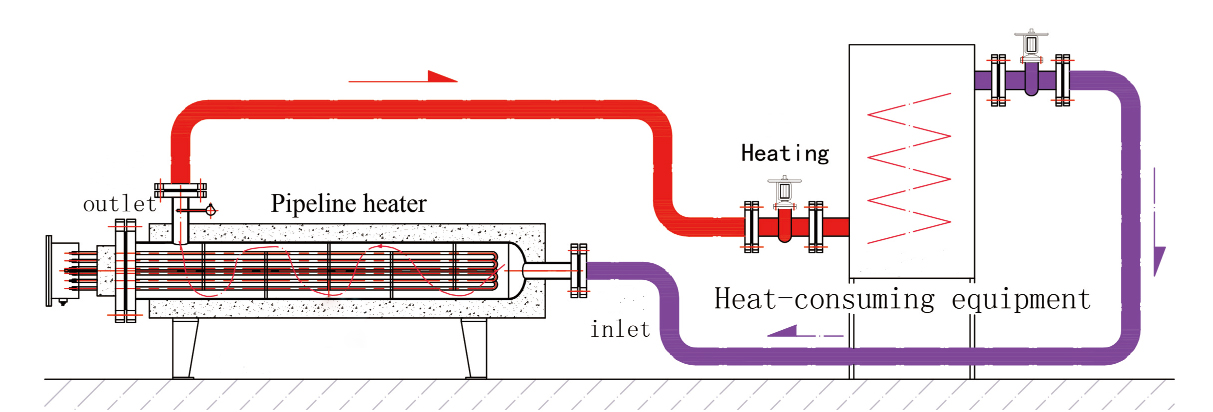

Ukuze ufinyelele izinga lokushisa olifunayo futhi lihlale lingaguquki, umoya ocindezelwe udinga ukushiselwa kabusha kusetshenziswa idivayisi yokushisisa. I-heater iguqula amandla kagesi abe amandla okushisa ngokusebenzisa isici sokushisisa sikagesi, ukushisa uketshezi oluphakathi (njengomoya ocindezelwe) futhi ikhuphule izinga lokushisa layo.

I-heater ifakwe isici sokushisa kagesi, futhi lapho umoya ocindezelweyo ugeleza ku-heater, inzwa yokushisa ekuphumeni izohlola izinga lokushisa lomoya ocindezelweyo. Uma izinga lokushisa lingahlangabezani nezidingo, iyunithi yokushisa iqala ngokuzenzakalelayo ukushisa umoya ocindezelwe ngesici sokushisa sikagesi.

I-heater isebenzisa isibonisi sedijithali sezinga lokushisa lesikhathi sangempela, futhi izinga lokushisa lilungiswa ngumlawuli ongase abe khona. Isici sokulinganisa izinga lokushisa kanye nemojula yokulawula iqedela ukubala ukulinganisa kanye neluphu yokulawula ukuze ibone ukulawulwa kwengxenye yokushisisa. Isignali yokulinganisa ithunyelwa kumojuli yokulawula ukuze ikhulise futhi iqhathanise futhi iboniswe esikrinini sokubonisa. Ngesikhathi esifanayo, inani le-analog lika-4~20mA lingakhishelwa ngaphandle ukuze kubonwe ukuqapha kwangaphandle okukude.

I-heater yepayipi yomoya ecindezelwe ifinyelela ukulawulwa okunembile kwezinga lokushisa kanye nokushisisa komoya ocindezelwe ngokusebenzisa ukufudumeza okuyisizayo kwezinto zokushisisa ngogesi ukuze kuhlangatshezwane nezidingo zezimo zohlelo lokusebenza ezahlukahlukene.

Isicelo somkhiqizo

I-heater yamapayipi isetshenziswa kakhulu endaweni yasemkhathini, embonini yezikhali, embonini yamakhemikhali nasemakolishi nasemanyuvesi nakweminye ilabhorethri eminingi yocwaningo nokukhiqiza yesayensi. Ifaneleka ngokukhethekile ukulawulwa kwezinga lokushisa okuzenzakalelayo kanye nokugeleza okukhulu kokushisa okuphezulu okuhlanganisiwe uhlelo kanye nokuhlolwa kwesesekeli, indawo yokushisa yomkhiqizo ayi-conductive, ayishisi, ayiqhumi, ayikho ukugqwala kwamakhemikhali, akukho ukungcola, iphephile futhi inokwethenjelwa, futhi indawo yokushisa iyashesha (siyalawuleka).

Icala lokusebenzisa ikhasimende

Umsebenzi omuhle, ukuqinisekiswa kwekhwalithi

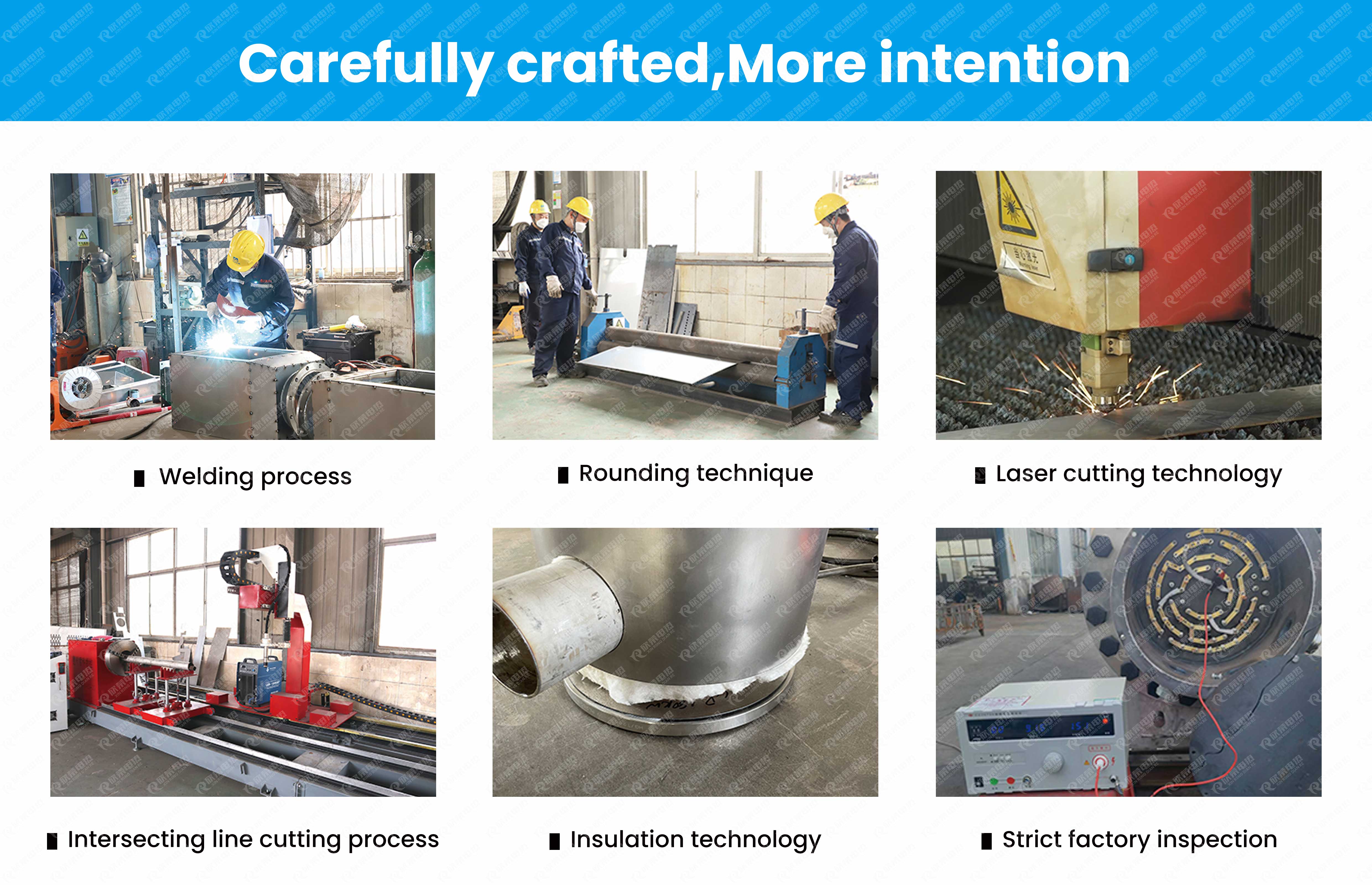

Sithembekile, singochwepheshe futhi siyaphikelela, ukukulethela imikhiqizo emihle kakhulu kanye nenkonzo yekhwalithi.

Sicela uzizwe ukhululekile ukusikhetha, masifakazele amandla ekhwalithi ndawonye.

Isitifiketi kanye neziqu

Ukupakishwa komkhiqizo kanye nokuhamba

Ukupakishwa kwezisetshenziswa

1) Ukupakisha emacaleni okhuni angenisiwe

2) Ithreyi ingenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende

Ukuthuthwa kwempahla

1) Express (isampula oda) noma ulwandle (oda ngobuningi)

2) Izinsizakalo zokuthumela emhlabeni wonke